Good information is the holy grail of asset management. Everyone is looking for complete, accurate and up-to-date information to make informed business decisions that will improve asset performance, reduce risk and lower costs.

In this quest, many asset-intensive organizations have invested heavily in asset information systems (e.g., EAM/ERP/CMMS) over the last 20 years. Yet, despite considerable expenditure, organizations complain that benefits have been slow to materialize and are difficult to measure. Managers say they still can’t access the information they need.

If everyone is after it, why is good information still so hard to get? What is missing?

Good asset management information is a product of several things. You often hear people, process and technology cited as key information drivers. That’s true, but there is a fourth piece that is essential for creating good asset management information, yet it is often overlooked. That piece is content.

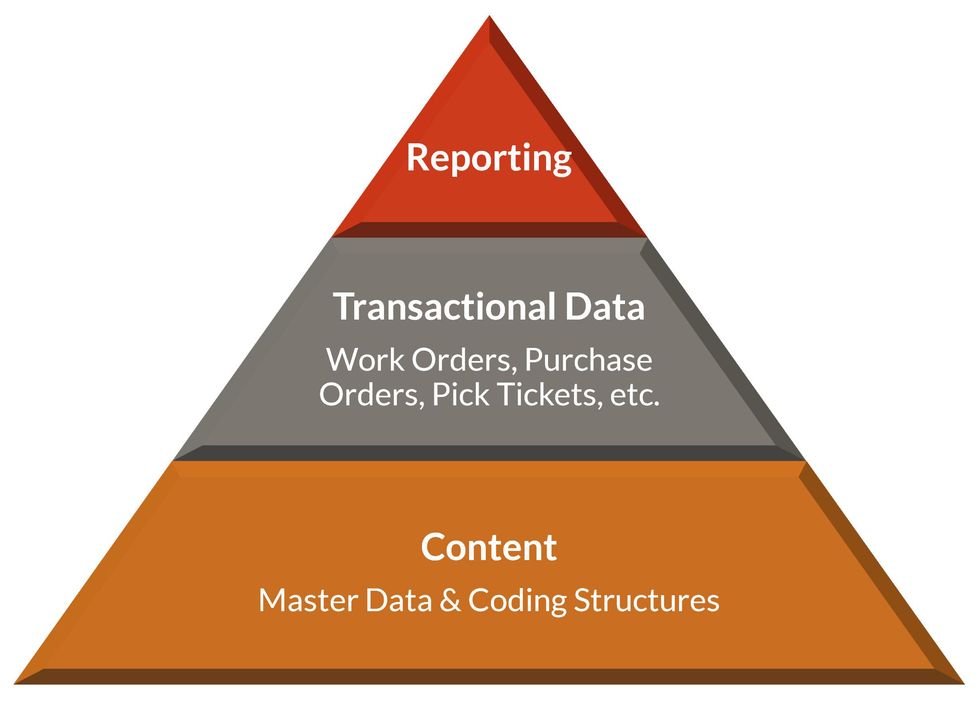

Figure 1: Layers of data in an asset information system

What Is Content?

Content refers to static data structures that are stored in the information system. It includes master data, such as the equipment master, materials catalog and vendor master, and coding structures, such as work order types, failure codes and equipment classes. (In general use, content sometimes includes transactional data, such as records of transactions conducted in the software system, or unstructured data, such as documents like manuals, drawings and contracts. In this article, however, content refers specifically to fixed, structured data that is preloaded into the information system.)

Master data provides a standardized library of information about an organization’s assets, materials, vendors and other business objects. Coding structures are used to sort, group and filter data. These two types of content are distinct, but they share a key characteristic: both are loaded into the system as opposed to being created by the system.An asset information system contains several layers of data. These include content, transactional data, and reports generated by the system from this data. Content is the bottom layer, the base on which transaction records and reports are built.

Content is foundational because it must be referenced when the system completes other tasks. Thus, developing good content is crucial if you want to pull useful information out of your software.

Content and the Information Pipeline

Content interacts with people, process and technology to create transactional data, such as work orders, pick tickets and purchase orders. Each time a transaction record is created, the system must reference existing system content. Work orders are created on equipment records, for example, and parts are issued from a materials catalog.

As transaction records are created, the system builds up a history of information about asset-related events. This transactional data is the basis for performance measurement and analysis. Mean time between failures (MTBF), equipment failure analysis, reorder point analysis and many other analytical tools rely on transactional data for their insights.

In addition to its role in creating transactional data, content also plays a key role in reporting, analytics and system usability. That’s why bad content is so lethal to good information; content is the starting point for everything the software system does.

Figure 2: The asset information pipeline

Content Challenges

Many organizations spend too little time developing content for their asset management software. This omission can manifest itself in several ways:

- Master data is incomplete, contains duplicate entries, has spelling or syntax errors, or does not follow standard naming conventions across the organization.

- The equipment master hierarchy is not structured for costs to roll up properly.

- Coding structures do not exist, or if they do, the code sets are incomplete or poorly designed.

Challenges such as these create major problems for system use and performance. Missing information, duplicate entries and bad codes wreak havoc with transactional data. They make it hard to locate records, forcing users to slowly scroll through the database to find the information they need. They also create problems with downstream information output. A poorly developed set of problem and failure codes, for example, makes it impossible to analyze the specific reasons for equipment failures.

In short, if you don’t get your content right up front, it will cripple your ability to pull rich, actionable information from the software system.

Content Solutions

Because content is so critical, content development activities, such as building an equipment master and establishing work order coding structures, should be a fundamental step in every asset information system implementation. With that in mind, this section provides guidelines for developing several key types of content.

Equipment Master

The equipment master is the table that contains all of a site’s equipment records. Most asset management software allows for different levels of equipment:

- Systems are collections of positions and/or assets that work together to deliver a required business function or service. (A wastewater collection and treatment system is a good example.)

- Positions identify a location in which an asset resides. Positions are in the engineering realm and are identified on piping and instrumentation diagrams (P&IDs). Position naming convention normally describes what the position does, for example, “Pump (A) for Crude Unit Charge System.”

- Assets are maintainable physical objects, such as pumps and compressors. Assets are the base unit of equipment information and the smallest tracking unit for capital investments. A useful method for describing assets is the noun, modifier, attribute, value system, as shown in Figure 3.

Figure 3: Noun, modifier, attribute, value naming system

Most asset management software supports the development of an equipment hierarchy. An equipment hierarchy is a logical way to break down the plant’s systems, engineering positions and assets. A well-designed hierarchy supports cost roll-up. For example, if the equipment hierarchy has been structured properly, the costs to maintain a certain pump will be rolled up to the engineering position and system to which that pump belongs.

Figure 4: A sample equipment hierarchy

Materials Catalog

The materials catalog contains records for all the materials the organization purchases. Some of these materials are managed in the storeroom, while others are purchased on demand for specific jobs.

Implementing a clean, structured catalog makes it easy to find parts and develop purchase agreements. Reducing mean time to repair (MTTR) and item costs are big money savers for an organization. As the saying goes, the dough is in the MRO.

Entries in the materials catalog have certain required fields. Each of these fields is used for a different purpose and has different data requirements.

- Item Number should be dumb and sequential. (Leave the intelligence for the other fields in the database.)

- Description must be clean without unnecessary syntax and standardized. It must employ a noun, modifier, attribute, value approach.

- Class provides a way to group items for enhanced searching and reporting.

- Commodity provides high-level grouping for vendor spend analysis.

- The United Nations Standard Products and Services Code (UNSPSC) is an open, global, multi-sector standard for classifying products and services. It enables facility-wide visibility of spend analysis, cost-effective contract development and full exploitation of electronic commerce capabilities.

Figure 5: A sample extract from a materials catalog

Reliability Codes

Reliability codes (e.g., problem, failure, action, cause) are the heart of asset reliability reporting. They allow users to generate reports on the cost and frequency of different failure types for different pieces of equipment. See Figure 6 for examples of these codes.

- Problem codes define the specific problem with a piece of equipment. They are best associated with a specific class of equipment, such as pumps, motors, heat exchangers and so on.

- Failure codes further define what failed on the piece of equipment, allowing deeper analysis to be conducted on the part or component that failed.

- Action codes identify the action the maintenance technician took to rectify the equipment issue. These codes are general in nature and apply to all equipment classes.

- Cause codes are used to further describe the reason “why” the asset was underperforming. They are not intended to identify the exact cause of the problem, but are captured to provide a starting point from which root cause analysis can proceed.

Figure 6: A selection of problem, failure, action and cause codes

Other Content

here are many other types of content to develop in addition to those listed, including both master data (e.g., preventive maintenance, vendor, standard jobs, etc.) and coding structures (e.g., work order classes, how found, maintenance technician delay, etc.). Understanding what each does and how each can help is fundamental to creating great asset management information.

Conclusion

In order to make good business decisions, decision makers must know how often a piece of equipment has failed, whether critical parts are being stocked, how much preventive maintenance is being completed on time and so on. Without good content, it’s impossible to come up with reliable answers to such questions. Thus, although it can take time and effort, content development is essential to getting the information you need.

If the content in the system is poorly developed, system performance will suffer, no matter how much you invest in software or practices. People, process and technology are important, but don’t forget about content. It just might be the piece you’re missing.