Artificial Intelligence (AI) in Manufacturing: Towards Zero-Downtime, Zero-Defect Operations

IMC-2020 Presentation 37:50 Minutes

by Mohamad Abuali, IoTco

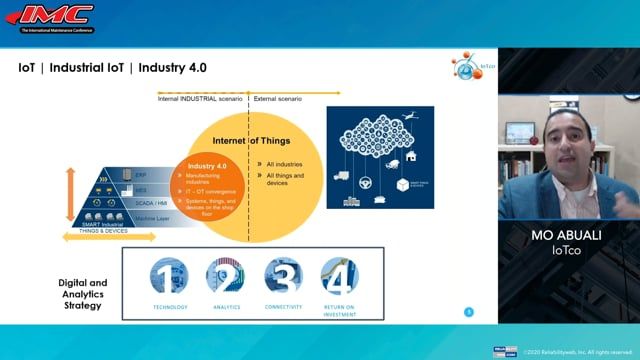

A reduction in unplanned downtime or a few percentages of scrap reduction can yield millions of dollars in savings for manufacturers. This compelling value proposition has resulted in significant investment and interest in using predictive maintenance and predictive quality solutions based on artificial intelligence (AI). Manufacturing firms are embracing digital transformation and leveraging AI and Big (Smart) Data metrics to achieve greater efficiency and productivity on the shop floor.

Despite this growing interest, many companies are not realizing solutions that can provide the desired valued and return on investment. Some less than successful solutions do not incorporate domain knowledge, or have poor data quality, or have an incomplete business case, or a lack of robustness in the AI machine learning models and approaches. This presentation will:

- Address many of those challenges and present compelling real-world examples with demonstrated value for rapidly deploying AI in manufacturing.

- Introduce a systematic methodology to define the business and technical problem and deploy state-of-the-art end-to-end analysis platforms from data collection to the delivery of the health and process information, as well as best practice guidelines on how these solutions can be maintained and improved over time.

- Present real-world manufacturing examples with ROI including stamping, casting, CNC machining, industrial robotics, among others. Examples in predictive maintenance that focus on reducing unplanned downtime will be shared along with case studies on predictive quality, in which the theme is improving quality and reducing scrap.

Lastly, the presentation will offer a practical approach and lessons learned on how manufacturers can start pursuing their digital transformation journey, in a phased approach, based on their level of digital maturity. The presentation and case studies will shed the light on how manufacturers can transform from a “fail and fix” to a “predict and prescribe” zero-downtime and zero-defect operation; keeping in mind cost, time-to-deploy, technology architecture, and scalability.