IMC-2016 - 49:58

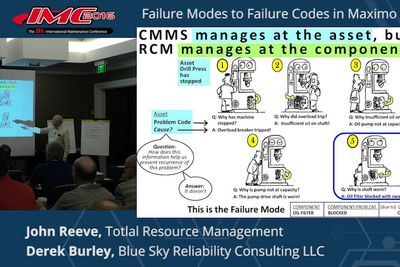

by Derek Burley, Blue Sky Reliability Consulting, LLC and John Reeve, Total Resource Management

When organizations wonder why their CMMS contains poor failure data, lacks analytical capabilities and is devoid of any form of failure analysis process, it is because the implementation team assumed the software itself would magically assemble meaningful data to identify worst offenders. Or, it is because the Core Team has not understood the benefits behind chronic failure analysis. Or, it is because the reliability engineer was never involved in the implementation and optimization of the system.

A few months ago, I was told the story of a maintenance engineer who spent 2 months reading through text fields on the work order to glean relevant information to help him identify the key failure modes of the asset in question. So why did this happen? Why weren’t the failure codes properly entered in the CMMS?

There are multiple reasons. But let’s first say this is one of the modern day puzzles within the CMMS community. After 2 decades (based on my field experiences) the majority of all sites - and all industries - have never successfully performed chronic failure analysis by leveraging actionable data direct from the CMMS. This is most unfortunate because 40-60% of all maintenance costs reside in this area.

This 3 hour seminar will involve the audience in a detailed discussion to discover a better solution. Key topic points will include:

Define failure data, failure codes, and failure mode (the language of RCM)

Define the ideal failure analytic, Pareto style.

Define the role of a Reliability Team

Describe how this entire process can be implemented.

Participants will absolutely walk away with an answer to this age old problem. Don't miss out on the largest potential benefit to your CMMS.