The absence of documentation and the presence of poor strategic maintenance methodology admittedly leads to running assets/plant on a run to failure strategy. In an effort to address such a situation, this article presents best practices and informed factors that asset managers and maintenance personnel must consider in order to select the right maintenance strategy for their asset or plant.

It is worthy to note that the maintenance strategy used for most assets is a function of how critical the asset is in the day-to-day operation of the plant, the availability of its parts, the value of the asset and the operating context of the organization.

Let’s explore some informed factors to consider.

The maintenance strategy should be customized.

This implies that it should consider all relevant factors of the situation at hand. For example, the needs of the company. The maintenance strategy selected should be unique to each company, but the underlying structure needs to be developed so that it can be comparable.

The strategy should follow work processes.

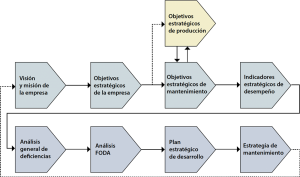

Here is how semantic scholar Antti Salonen describes the different parts of the schematic flow of the work process:

- Company vision and mission – The strategy should be based on the company’s vision and mission.

- Formulation of the strategic goals of the company – These goals should be supported by all functional strategies. Regarding the maintenance strategy, it is essential to consider not only the overall strategic goals of the company, but also the goals of production, which is the customer to the maintenance organization.

- Define the strategic goals of maintenance – The strategic goals of both the production department and the company should be considered and the goals should reflect both effectiveness and efficiency. This is done in order to satisfy all stakeholders.

- Tie the strategic goals to strategic performance indicators – The performance indicators are measured in order to evaluate the fulfillment of the strategic goals. Preferably, all stakeholders, such as the production department and the owners, should be involved when choosing the performance indicators. With this approach, acceptance of the strategy among the stakeholders will increase.

- Perform an overall gap analysis – Address current or potential gaps in maintenance performance. Once this is done, identify factors that may potentially influence the gap between current and desired levels.

- Perform a strengths, weaknesses, opportunities, threats (SWOT) analysis – Address the identified gaps in relation to the factors considered strategic for the development of the maintenance function. From the results of the SWOT analysis, make a list of actions to be taken.

- Determine a strategic development plan – This plan can be set up by prioritizing the actions identified from the SWOT analysis.

- Formulate the maintenance strategy – When the strategic development plan is in place, the maintenance strategy can be formulated.1

Figure 1: The schematic flow of the work process

The maintenance strategy should be selected in relation to the production and business activities.

This means there is a need to understand how the maintenance function will affect the dynamic need of the production department. This is due to the fact that production and maintenance objectives are inseparable. Production and maintenance objectives also need to be compatible with the company’s objectives in order to choose the right maintenance strategy that fits the business and the asset.

In Figure 2, the larger circle illustrates the strategic thought process of the maintenance manager. This thought process starts with the maintenance objective of the plant or the assets.

Figure 2: A business-centered model (BCM) for selecting the right maintenance strategy2

A maintenance strategy should function as a road map that allows and includes alternatives; it is not meant to go in just one direction.

The maintenance strategy must remain flexible so it can change with the company’s situation. The road map can be created based on results from benchmarking and observations of the company’s own best plants.

In order to formulate a maintenance strategy and produce a maintenance plan, the following questions need to be answered:3

- What should be done?

- Which are the most important items or critical assets?

- What are the legal requirements to be considered?

- When can the work be performed in order to avoid loss of production?

- In which frequency should surveys, inspections, work and tests be carried out?

- Where does the money come from?

A model for the formulation of a maintenance strategy.4

Maintenance should be considered as a partner within the business, with the shared overall aim to produce and sell products at an acceptable margin of profit. For this to be achieved, it must be understood that all functions within the business contributes to profitability. Thus, the maintenance function should align with the overall business goals. Before developing or selecting a maintenance strategy, the need for change should be established. Within the maintenance philosophy, change should be embraced as a major expectation and constituent. The maintenance strategy development process starts with stating the maintenance philosophy, which is an expression of the maintenance function’s role within the company and the chosen approach for how to fulfill it.

The next step is to consider the aims and objectives of the maintenance function. The aims can be at corporate, production and maintenance levels, and the objectives must respond to the driving forces from production.

The third step is to assess and evaluate maintenance practices and issues. Figure 3 represents the range of maintenance policy sectors and corresponding practices to consider for this assessment, which, after completion, may be used to develop a maintenance program. Then, tactics for how to integrate existing practices with new ones should be developed.

Figure 3: Range of maintenance policy sectors and corresponding practices

The last step is to determine the implementation plan.

Other informed factors to consider are:

- Condition or nature of the assets/plant;

- Passing of time or the age of the asset;

- Failure rate triggers which type of maintenance strategy to be chosen;

- Each unit of the equipment or facility;

- Cost reduction or effectiveness;

- Work environment and safety;

- Criticality of the asset and the kind of equipment to be maintained.

Conclusion

In summary, the type of maintenance strategy selected should depend on the critical nature of the equipment, availability of spare parts, size and nature of the organization, available technology and the organizational maintenance policy.

References

- Salonen A. “Strategic Maintenance Development in Manufacturing Industry.” Thesis, Mälardale, 2011.

- Kelly, Anthony. Maintenance Systems and Documentation, 1st Edition. Oxford: Butterworth-Heinemann, 2006.

- Gupta, A.K. Reliability, Maintenance and Safety Engineering. South Orange: University Science Press, 2009.

- McAllister K., Armstrong, J., and Wilson, A. “Asset Maintenance Management, a guide to developing strategy and improving performance.” Surrey: Conference Communication, 1999.