The Larger the Project, The Greater the Chance of Cost Overrun

All you have to do is look at the headlines:

- Navy Carrier Cost Overruns May Hit $1.1 Billion, January 2012;

- Lockheed Martin F-22 Raptor, October 2014;

- Navy’s $115 billion Price Tag for New Submarines Will Probably Grow Higher, April 2019

Have the project management skills of the DoD become too lax? Within the world of asset management, construction and alterations are also part of the budget. As asset management professionals , are we paying attention?

Scheduling is a Lost Art

Many decades ago, I left a scheduling career to become a CMMS professional. The world of asset management of course was much more expansive – and interesting. The odd part about this journey is how the CMMS community talks about scheduling but knows very little about the subject. This is where the statement, “You don’t know what you don’t know” applies.

Natural Intersection

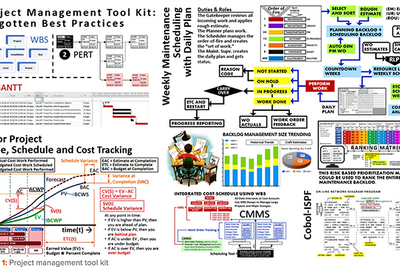

There is a natural intersection between the computerized maintenance management system (CMMS) and project management. If you link the WBS with the work order and the work order with the schedule, you have all of the data elements you need. The WBS provides a summary hierarchy which provides the ideal structure for cost reporting. Senior management does not want to see work order details let alone a 1000 activity schedule.

Facility project managers and architects manage new construction and alterations. They would benefit from having a WBS connected to work orders, and a construction schedule. When a new building is delivered, there can be thousands of assets. These new assets need to be registered and given the right maintenance strategies and scheduled. In the utility and oil/gas industry, shutdown/turnaround/outage (STO) management is a primary concern. Regardless, cost/schedule management starts inside the CMMS.

The Elusive Weekly Schedule

There are many reasons why this process can go sideways. Consequently, 90 percent of all sites have never successfully created a resource-level weekly schedule. Some just print out a list of open work and hand that to the maintenance staff to figure out. Some just focus on emergency and urgent work blended with generated preventive maintenance (PM) work orders. The problem lies with all the other work in the backlog as to how best to manage. And even if all the work orders had a craft estimate, questions still exist as to which ones should be done first and how much work should be scheduled based on craft availability.

Once Upon a Time

Once upon a time, there was a company that marketed project management software. It sold scheduling software and project cost tracking. These two products could be integrated through a work breakdown structure (WBS) at the cost account level to provide the ideal project management system. This software included a full function scheduler that could manage any size project and plot graphics of all types (e.g., bar charts, histograms and network diagrams). At one time, about 50 percent of all the U.S. nuclear power plants in construction/start-up and operational phase used this software.

Then the Mainframe Died

Change happens. For the most part, mainframe software did not convert over to today’s technology. Software companies were in a rush to release and decided to build from scratch. Although the new technology is absolutely brilliant, there was some loss of functionality. The current CMMS products there are weak scheduling interfaces. Beyond that, there is also a general lack of knowledge in the CMMS community regarding project management.

Project Management Best Practices: 1-2-3

The project management concepts taught 30 years ago in project management classes still hold true today. Rule number one was if you build a large project (e.g., construct a nuclear power plant), you should first create a WBS. This design ensures that no scope is forgotten and it provides scope tracking (i.e., additions) once underway. The cost account (CA) element typically stores the budget values. The WBS is also a good place to capture dollar transactions (i.e., movement between cost elements). Lastly, it is the WBS-CA that provides an intersection point for CMMS work order actuals and schedule activity percent complete for cost reporting.

The second rule states that the scheduler must build the story just like a newspaper reported. He cannot build a schedule just because he is a scheduler. He must conduct research, create fragnets, and piece things together – similar to a newspaper reporter.

Once the schedule is assembled, then it is time for reviews. In a nuclear power plant, the scheduling group will have a senior reactor operator, shift supervisor, and outage manager at hand. This person will ask for a print-out (or graphic) showing the critical path. Once validated, then the scheduler will perform resource leveling. The finish date may move further out (very likely) and once again an iterative review process is conducted.

Once the schedule is finalized, a nice looking logic bar chart under a timeline is produced for readability purposes so all stakeholders can clearly see dates for intermediate milestones and, of course, the project’s finish date.

10 Requirements for the Ideal Project Management System

In a perfect world, it would be much easier if the CMMS [green] could be set up to support project management best practices – starting with a WBS option [blue]. The CMMS however should be able to do resource-leveling as this is basic math. All that is needed then is an integration to a formal scheduling tool [tan].

Figure 2: Integrated scheduling solution

Here Are 10 Future World Requirements:

- Allow for a countdown scheduling design. The scope would be tied down for several weeks in advance. The T-0 week is the execution week. The weeks would be stored/managed inside the CMMS.

- Some organizations only want a resource-leveled weekly schedule. This should be a single-click action direct from the CMMS creating a tabular report. The weekly maintenance schedule could also feed the daily plan, showing a 2-dimensional report design.

- The CMMS work management product would provide a capability to generate and store a rough estimate.

- In the case of a weekly maintenance schedule, ability is needed to properly capture carryover work, which includes estimates to complete (ETC) by craft and an optional restart date, against the work order. The ETC values, if entered, would then be used in subsequent resource leveling calculations.

- Provide ability to store major projects inside the CMMS as a WBS and graphically display the WBS chart. Users should be able to graphically build a WBS using drag-and-drop tools.

- Provide ability to link WBS-CA to work orders, capture actuals on work orders (CMMS), store budgets in WBS, and roll up percent complete from the project scheduling tool integrated with WBS-CA codes. An example scheduling tool would Primavera.

- Provide ability to produce a project cost tracking report using indented levels. The moment an outage finishes, the chief financial officer (CFO) wants to see total costs.

- With access to a formal scheduling tool provide ability to create and plot WBS hierarchies, bar charts, and network diagrams.

- The project scheduling software would have the ability to perform advanced progressing techniques, i.e., progress against a data date. Additionally, it would provide the ability to add work to the CMMS from the scheduling tool.

- Provide the ability to display a work schedule in a compatible calendar format.

Outage Manager Requirements

For outage managers, these 10 actions represent the best use of project management software.

- Create an initial outage schedule showing all required activities with milestones by interviewing all stakeholders. Note that this scope control starts many months/years in advance of a scheduled outage.

- Use an iterative review process to bring total cost down to CFO allowed expenditures and duration based on prioritization by removing/adding scope.

- Validate critical paths by analyzing driver activities using a critical path walker tool. Perform automatic resource leveling and final validation of milestones.

- Assess risk points by identifying ways to mitigate risk.

- Create mockups to test areas of risk and complexity. Validate craft skills.

- Review safety measures for all, including contractors.

- Freeze the schedule and outage scope by establishing outage scope control measures. Track scope additions and approvals.

- Establish procedures for capturing outage progress. This should be done on a daily basis by shift.

- Transfer contingency funds and document movement.

- Output an indented project cost tracking report at any time, especially right after the outage completion.

How Much Software Do You Need?

You can buy software to do anything. But, first, take a hard look at your CMMS to determine what can be configured internally. And through clever use of applications, output can be generated that promotes project management best practices.