Maintenance is intended to achieve inherent reliability through repair, restore, renew, replace and to bring our assets back to a healthy, steady-state operating condition. Defects created through maintenance workmanship can be a difficult concept to understand and to turn-around.

What is a defect?

According to Uptime Elements Reliability Framework and Asset Management System, defects are anything that creates waste, erodes value, reduces production, compromises health, poses safety risks, or negatively impacts the environment.

What is defect elimination?

Defect elimination is about eliminating the things that are creating the defects.

Current Reliability Practices

In most reliability improvement programs, small teams of reliability specialists are typically focused on addressing the 20 percent of assets that are the “bad actors” where 80 percent of the reliability risk exists.

While this is a value-added function, it is not enough to stem the pace of defects entering into the system through careless work habits. If you added up all the defects that are too small to even name, you may find they present as much risk as your top "bad actors". They are mainly "cultural" defects at this point but can eventually work their way onto the "bad actors" list if left unattended.

Successful high reliability organizations engage and empower a cross-functional frontline workforce in self-directed, action-oriented defect elimination activities to create the dual benefits of reducing the defects that cause many of the frequent failures and creating a culture of reliability leadership at all levels of the organization.

In the The ABC’s of Failure, Winston Ledet states that:

- Aging assets account for 4% of failures

- Basic Wear and Tear account for 12% of failures

- Careless Work Habits* account for 84% of failures

*Careless work habits, a concept developed by Ledet in his foundational book, Don’t Just Fix it, Improve It! (ISBN: 9780982516317) simply means not providing the care that assets need to run perfectly.

Careless work habits ARE NOT the same as working in a malicious or irresponsible way. They are the everyday, small actions that are mostly preventable, however, because they are not distinguished or acknowledged, they remain covered by a veil of invisibility. You cannot improve what you do not acknowledge or cannot distinguish.

Corrective Maintenance Defect Source Benchmarking

In a DuPont Corrective Maintenance benchmarking (included 1000 Corrective Maintenance Work Orders selected at random), Ledet tracks the original sources of defects that lead to the required correction and reveals:

20% originated through raw material and process input defects

30% originated through operational discipline defects

20% originated through maintenance workmanship defects

10% originated through maintenance and repair spare parts and material sourcing, storage and handling defects

20% originated through specification, design, build, procure and commissioning defects

Maintenance Workmanship Defects

When presenting this I am often asked what is behind the 20% maintenance workmanship defect statistic.

Based on our own experience and validated by the Ledet research in "Don't Just Fix It - Improve It!" and addition anecdotal research conducted by James Reason and Alan Hobbs in their book "Managing Maintenance Error" we have compiled the following list of of the modes or mechanisms that can create defects from maintenance workmanship.

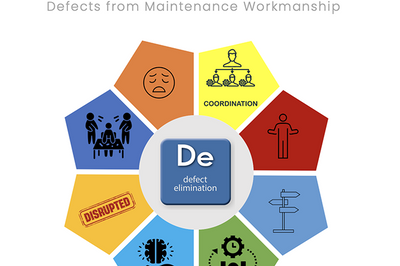

Defect Elimination: Defects from Maintenance Workmanship

Tiredness

Example: working longer than twelve hours creates fatigue or working without regular healthy sleep

Pressure

Example: being asked repetitively “How long is it going to take?”

Interruptions

Example: interrupting current job and being called to a new, more urgent job

Excessive reliance on memory

Example: memory lapses are the most common error

Inadequate coordination

Example: people making unspoken assumptions about a job

Unfamiliar jobs

Example: jobs that are not part of your normal duties – even if you have done so prior

Ambiguity

Example: jobs where you are unclear and not sure of what is going on

Highly routine procedures

Example: any routine job you can perform with your “eyes closed”

Summary

In High Reliability Organizations, empowered, cross-functional teams have regular forums or continuous improvement team meetings that are safe spaces and have no "authority hierarchy". People are invited to have crucial conversations about the things that are adding defects to the system faster than the maintenance and inspection system can remove them.

Of course there is more to an effective defect elimination culture than the above. My hope is that this article encourages you to consider adopting Uptime Elements Reliability Framework and Asset Management System which includes an effective defect elimination culture as natural self-expression.

For more on defect elimination click here

- Eliminating the Sources of Poor Reliability: Defects ›

- Defect Elimination From a CMMS Perspective ›

- Becoming a High Reliability Organization Through Defect Elimination ›

- Defect Elimination in the context of Uptime Elements ›

- Reliabilityweb Defect Elimination Short Course and Exercise [02] ›

- A Common Sense Approach to Defect Elimination ›

- Why Defect Elimination Is Effective ›

- Defect Elimination: Left to Right & Right to Left ›

- Root Cause Analysis and Defect Elimination ›

- Reliabilityweb Get the Bugs Out With the Uptime Elements ›