Organizations that aggressively pursue operational excellence have the best opportunity for enhanced profitability. They also realize value provided from a purpose-built computerized maintenance management system (CMMS), precisely configured to extract knowledge and manage by exception. However, the CMMS is only as good as the surrounding process and roles. Hence, a comprehensive plan is needed that encompasses the entire asset management system to enhance reliability, workforce productivity and job safety.

Organizations that aggressively pursue operational excellence have the best opportunity for enhanced profitability. They also realize value provided from a purpose-built computerized maintenance management system (CMMS), precisely configured to extract knowledge and manage by exception. However, the CMMS is only as good as the surrounding process and roles. Hence, a comprehensive plan is needed that encompasses the entire asset management system to enhance reliability, workforce productivity and job safety.

What Is a Purpose-Built System?

Very few organizations know what they want, even after their CMMS goes live. A good implementer blends software knowledge with industry best practices. The implementer also trains the core team to seek continuous improvement through benchmarking activities. As a result, leadership may not know exactly what they want, but they are designing the CMMS with the end goals in mind. Using the Uptime® Elements as a framework for reliability, empowered by a configurable CMMS, leadership can set their own pace and build as they go.

The Reliability Journey

The Uptime Elements provide a critical relationship between the CMMS database and reliability engineering. It is this relationship, however, that is oftentimes underdeveloped. In order to pursue the shortest path to value, a clear road map is needed that addresses the hard subjects, like:

- How do you reduce reactive maintenance?

- How do you extract bad actors?

- How do you implement defect elimination?

- How do you verify that your preventive maintenance/condition-based technology program is set up correctly?

- How do you create a living program in support of failure mode refinement?

If you can’t make data-based decisions by leveraging failure data in your CMMS, then what are you doing?

You Can’t Install Reliability

Reliability is the probability that a system will perform satisfactorily for a given period of time under stated conditions.

Reliability Engineering is a subdiscipline of systems engineering that emphasizes dependability in the lifecycle management of a product. Dependability, or reliability, describes the ability of a system or component to function under stated conditions for a specified period of time.

Asset reliability does not magically improve when a CMMS goes live. The software may be best of breed, but it is the culture of the organization that drives excellence. Quite often, leadership does not clearly define the endgame or provide a long-range plan to get there. Or, the implementation team does not involve reliability leaders in defining the output essential to measuring performance. Once the CMMS is operational, there also needs to be a strategy for optimization and sustainment other than vendor recommended software upgrades.

The ideal asset management system is one that is based in reliability. And a CMMS, if properly set up, will facilitate data-based decision making.

Where Are the Roadblocks?

- An executive level policy that does not encourage employees to attend off-site venues to broaden knowledge in asset management

- Reliability engineer who is really a maintenance engineer

- No formation of a core team to integrate software functionality with asset management best practices; unclear business rules; no benchmarking activities

- No CMMS utilization plan that states how the product should be used to add value to the organization; this plan would identify the shortest path to value

- A working level that sees the asset management system as a people tracking system

- No business analyst to regularly interview the working level to identify process flaws, lack of training and declining morale

- No planner/scheduler to improve workforce productivity and backlog reduction

There Is No Guidebook for Utilization and Optimization

4 Ways to Implement

When implementing a CMMS, management has three options:

- Replicate existing legacy system processes;

- Rely on software vendor suggested processes;

- Perform some combination.

There could be a fourth option: Combining industry best practices and advanced processes. This combined approach assumes the consultant has knowledge to share regarding best practices. But, regardless of the path chosen, without a clear understanding of output requirements and analytical report design, you may not even be capturing the right data from day one. Therefore, the individual or group who has the authority to define the intended usage of the CMMS should determine the long-term success of this system.

Underutilization of CMMS Places Organization at a Disadvantage

Software by itself will not succeed in a poorly aligned culture. After all, the CMMS is just one of 36 elements in the Uptime Elements framework. However, the CMMS is often underutilized, misused and even misunderstood. The software vendor will not be able to provide an industry specific process map, therefore, it is up to the asset stakeholders and core team to build this map.

Advanced Processes Deliver Greatest ROI

Most implementers will implement the CMMS using basic processes since this is the quickest and cheapest way to reach the go live milestone. Basic processes, such as creating and completing work orders, are easily understood, but advanced processes, such as chronic failure analysis, backlog management and future scheduling, are frequently not pursued. A CMMS, unlike other software programs, only achieves greatness when surrounding processes are optimized and decision-making tools are enabled. Admittedly, these advanced processes are more complex and take more time to implement, but they enable decision makers to maximize value.

The Goal of Operational Excellence Must Come from Within

The first step toward operational excellence is to establish an awareness and understanding within the executive team. The executive sponsor should have training in asset management strategy. More importantly, the concept of advanced processes should be defined and linked to the return on assets (ROA). In a perfect scenario, the CMMS implementation contract would be worded to identify both short-term and long-term goals. Either way, the onus is on the sponsors and reliability leaders to clearly communicate strategies for success.

Investigating the Sub-Elements of a CMMS

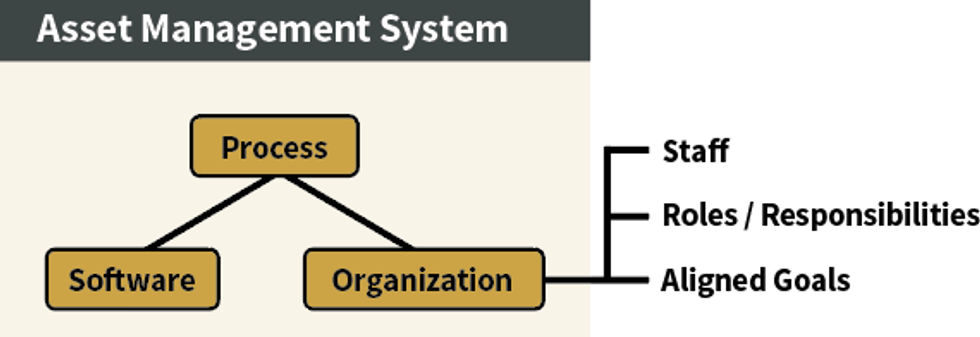

Every CMMS has user applications. Examples include work orders, assets, locations, inventory and purchasing. But rather than focus on product navigation, let’s look at the things that really matter, such as process and roles.

Advanced Processes

Root cause analysis (RCA) might be done once or twice a month. An RCA also might have trigger points that mandate performance. However, it is the smaller, recurring failures that cause 40 to 60 percent of maintenance costs, so they deserve greater attention. If reliability leaders want to stop the problem at the origin, then defect elimination should be pursued. The combination of these techniques, plus work order (WO) feedback, helps ensure the right work is being done by the right staff at the right time.

CMMS Design with the End in Mind

Too many implementers focus only on the software. This means they perform rudimentary setup per the product training manual, load data and train staff. But, if the implementers were to involve the reliability engineers, they might get an entirely different emphasis. Reliability engineers benefit the most from failure data that is properly captured to support reliability engineering. They would start with a failure analytic design that enables the reliability team to drill down on failure modes once the bad actors are defined. In some cases, these new output requirements require configuration of the input screens to provide the right data, such as a validated failure mode.

RCM for Asset Management

Setting up reliability-centered maintenance (RCM) for asset management can be illustrated with six primary blocks. The asset registry must be populated with criticality that is risk based. Using this criticality, the best method for strategy creation, for example RCM analysis or preventive maintenance (PM) optimization, can be determined. In some cases, the original equipment manufacturer (OEM) guidelines are used or simply, peer-to-peer recommendations. These strategies are then converted to PM servicing activities or condition-based technology (CBT) routes. Work can then be properly planned, scheduled and executed. Using a failure analytic, bad actors can be presented to the reliability action team for analysis and action.

Stretch Goals Are Ideal

Best in class organizations continually seek new ideas and technologies in support of their goals. Some improvement initiatives can take a while to implement. And, every organization has the right to use the CMMS in the manner it sees fit. But, leadership should not assume there is a guaranteed benefit from poorly implemented systems. Therefore, if an organization wishes to pursue the highest levels of asset management, it needs to configure the software and surrounding processes, including stretch goals, to maximize value.

If leadership leaves it up to individuals to pursue continuous improvement, the opportunity for greater results may be missed. If stretch goals are used, there is a greater chance of success through awareness. You may not always make these stretch goals, but if they are not established, you absolutely will not. The other benefit of this strategy is that by defining the endgame or target goal(s), you can then, as a group, sit down and lay out the logical steps to get there. This becomes the road map, with a timeline.

Key Elements of an Asset Management System

In summary, there are many elements of an asset management system. The CMMS should be purpose-built to manage by exception and improve ROA. Leadership should be informed and goals aligned. But remember, it is the advanced processes that provide the biggest bang for the buck.

Demanding Excellence from Your Asset Management System by John Reeve, August 2019 by Reliabilityweb.com Publishing.

For more information:www.reliabilityweb.com/bookstore

Organizations that aggressively pursue operational excellence have the best opportunity for enhanced profitability. They also realize value provided from a purpose-built computerized maintenance management system (CMMS), precisely configured to extract knowledge and manage by exception. However, the CMMS is only as good as the surrounding process and roles. Hence, a comprehensive plan is needed that encompasses the entire asset management system to enhance reliability, workforce productivity and job safety.

Organizations that aggressively pursue operational excellence have the best opportunity for enhanced profitability. They also realize value provided from a purpose-built computerized maintenance management system (CMMS), precisely configured to extract knowledge and manage by exception. However, the CMMS is only as good as the surrounding process and roles. Hence, a comprehensive plan is needed that encompasses the entire asset management system to enhance reliability, workforce productivity and job safety.