What Is ISO14224?

In the petroleum, natural gas and petrochemical industries, great attention is being paid to safety, reliability and maintainability of equipment. In this respect, data on failures, failure mechanisms and maintenance related to these industrial facilities and their operations have become of increased importance. Standardization of data collection practices facilitates the exchange of information between relevant parties, such as plants, owners, manufacturers and contractors throughout the world.

ISO14224 describes data collection principles and associated terms and definitions that constitute a reliability language that can be useful for communicating operational experience. A major objective of this international standard is to make it possible to exchange RM data in a common format between owners, operators, original equipment manufacturers (OEMs) and other relevant vendors and contractors.

This international standard does not apply to the following:

- Data on direct cost issues;

- Data from laboratory testing and manufacturing;

- Complete equipment data sheets;

- Additional on-service data;

- Methods for analyzing and applying RM data.

Benefits of RM Data Collection and Exchange

There are several aspects of benefits that can be realized by properly collecting and analyzing quality RM data. Some of them are:

Economic

- Cost-effective design to optimize capital expenditure (CAPEX);

- Cost-effective operation to optimize operational expenditure (OPEX);

- Improved profitability through reduced revenue loss.

General

- Being able to operate (operator license);

- Life extension of capital equipment;

- Improved product quality.

Safety and Environmental

- Improved personnel safety;

- Reduced catastrophic failures;

- Reduced environmental impact.

Analytical

- Improved decision-making;

- Qualified benchmarking;

- Better predictability.

The application of this standard is recommended for collecting data during the whole lifecycle of an asset, including installation, start-up, operation, maintenance and modification, until the asset is decommissioned or retired.

Some important aspects for creating the data structure are:

- Defining Equipment Boundary: For each equipment class, a boundary should be defined indicating what RM data is to be collected under each equipment class. Boundaries should avoid overlapping among different equipment classes.

Figure 1: Equipment boundary

The ISO14224 taxonomy defines different levels at which data needs to be collected.

Figure 2: ISO14224 taxonomy

Levels 1 through 5 represent a high-level categorization that relates to industries, plants and their sections, regardless of the equipment units involved. It is necessary to have the operating context of each location/equipment to make the analyses more meaningful.

Figure 3: Location operating context

Levels 6 through 9 are related to the equipment unit, with the subdivision in lower indenture levels corresponding to a parent-child relationship. The number of subdivision levels for the collection of RM data depends on the complexity of the equipment and the use of this data.

For effective collection and utilization of RM data, these data categories should be used:

- Equipment data

- Classification data (e.g., industry, plant, location, system);

- Equipment attribute (e.g., manufacturer’s data, design characteristics);

- Operation data (e.g., operating mode, operating power, environment).

Table 1: Equipment Data

Failure data

- Identification data (e.g., failure record number and related equipment that has failed);

- Failure data for characterizing a failure (e.g., failure date, items failed, failure impact, failure mode, failure cause, failure detection method).

Table 2: Failure Data

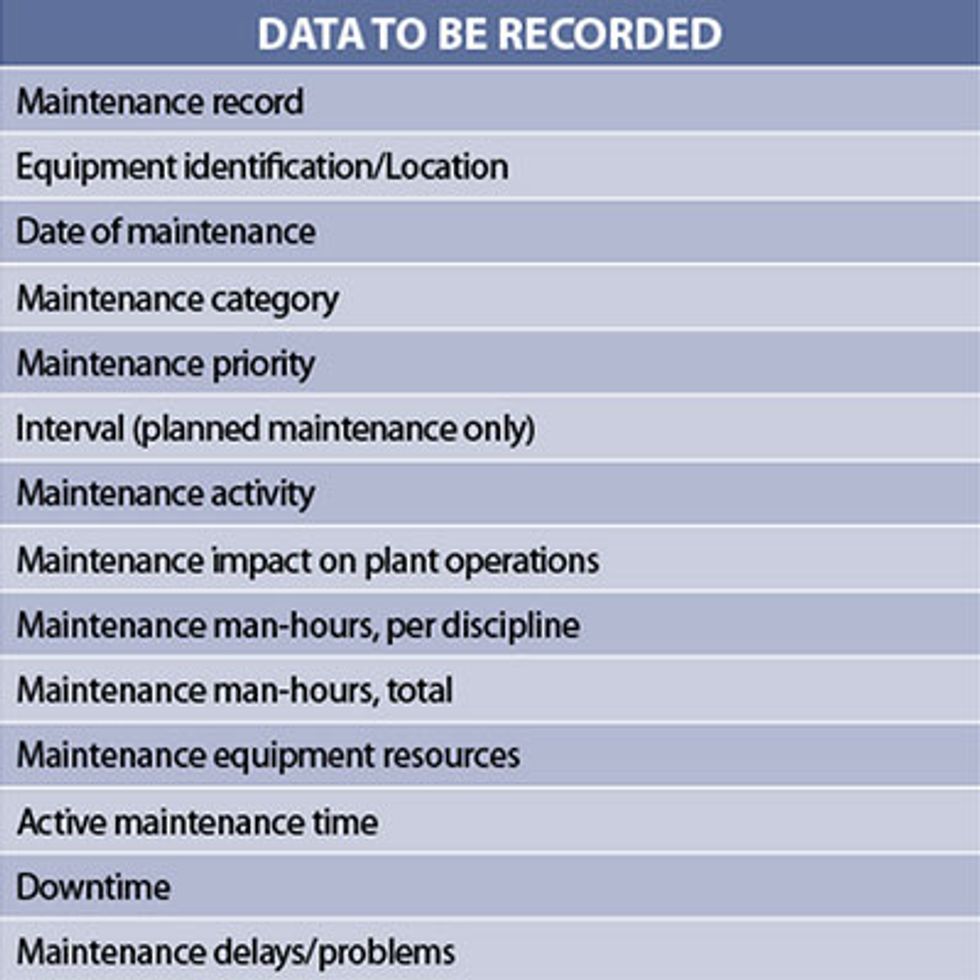

Maintenance data

- Identification data (e.g., maintenance record number);

- Maintenance data (e.g., date of maintenance, maintenance category, etc.);

- Maintenance resources (e.g., labor, spares, tools/other services);

- Maintenance times (e.g., active maintenance time, downtime).

Table 3: Maintenance Data

- Maintenance Times: The standard recommends collecting two main calendar times - downtime and active repair time - during maintenance.

Figure 4: Maintenance times

It has been observed that many companies ignore the importance of collecting RM data during the initial project stage and, hence, their EAM system lacks this data for future use when the owner/operator needs it badly to make important decisions. Many times, the EAM system is designed by the engineering, procurement and construction (EPC) contractor to meet contractual obligations. Modifying the system at a later stage requires more effort and is never cost effective. Moreover, by the time the client realizes the consequences, a lot of useful data is already lost.

There are several challenges that keep companies away from what they should be doing:

- Contractual complexities;

- No direct involvement from the owner/operators at an early stage, the EPC manages the show;

- Conflict of interest within involved parties during plant commissioning;

- Lack of advisory skills in the team and/or subject matter experts (SMEs) involved;

- Non-availability of the right resources on the implementation partner's team.

The result of this problem is an inefficient EAM system. Companies either create a bunch of systems struggling to operate in a cohesive way, or look for some point solutions to fill these gaps at a later stage. This increased complexity leads to a reduced adoption of such solutions and a high cost for system maintenance. In such a situation, it's difficult to make the right decisions and/or analysis from the implemented system.

Therefore, choosing the right package, the right implementation partner with the right domain skills at the right time is very important to a successful EAM implementation, especially in the oil and gas industry.

Above all else, the most important thing is to inculcate discipline in the workforce to collect the right quality data. Merely having a system in place won't help until you capture the right quality data at the appropriate time.

Remember, data gathering is an investment. You can perform better analysis with quality data only. As such, you need to ensure that you have the right checks and controls built into your business process to capture this data.

References

International Organization for Standardization. ISO14224:2006(E) - Petroleum, petrochemical and natural gas industries - Collection and exchange of reliability and maintenance data for equipment. Geneva: 2006. http://www.iso.org/iso/catalogue_detail.htm?csnumber=36979

Disclaimer: The viewpoints made in this article are based on the experience and opinions of the author and do not represent the views of IBM.

Neeraj Gupta is a Senior Solution Manager at IBM Global Services. Mr. Gupta has 19 years of experience in plant maintenance, asset and inventory management, and business and systems. His key industry focus is oil and gas, but has worked with clients in mining, aero, chemicals, utilities and the retail industry, mainly on business process reengineering and solution architecture areas.

Neeraj Gupta is a Senior Solution Manager at IBM Global Services. Mr. Gupta has 19 years of experience in plant maintenance, asset and inventory management, and business and systems. His key industry focus is oil and gas, but has worked with clients in mining, aero, chemicals, utilities and the retail industry, mainly on business process reengineering and solution architecture areas.