Since the beginning of time, human beings have survived and evolved through the use of tools. Tool usage is the basis for both ancient and modern engineering advances. With the advance of modern technologies, terms like artificial intelligence (AI), Industrial Internet of Things (IIoT) and Industry 4.0 are now more frequently used than robust engineering tools, like failure mode and effects analysis (FMEA) and root cause analysis (RCA).

In order to stay up-to-date, modern engineering needs to embrace the fast pace of the digital era, adapting its practices to keep up with a wave of technological breakthroughs with the advance of the Industry 4.0 revolution.

This article reviews some interesting and cost-effective examples of tools and methodologies rediscovered through the eyes of AI, analytics and business intelligence tools. By stimulating ideas, it can help your reliability and manufacturing excellence journeys to be faster, simpler and more sustainable.

FMECA – A New Way to Empower Your FMEA’s through Analytics

Among a broad range of options, failure mode, effects and criticality analysis (FMECA) is a good choice, not just for design and qualification steps, but to empower maintenance strategy, asset management and facilities maintenance.

1 Criticality (the C in FMECA) gives a risk-based bonus that allows the failure modes to be prioritized. Note that the C is not asset criticality, but for criticality of the failure modes.

Although the FMECA concept is not new, business intelligence tools can boost FMECA and refresh its usage. Using analytics, it is possible to filter the data with assets, locations and operating units, calculating criticality parameters as failure effect probability, modal failure rate, failure mode criticality, and so on.

Calculations can be automated with equations fed by queries on auto loops with analytics resources. Thus, years of information in your computerized maintenance management system (CMMS) are available for practical use — far beyond spreadsheets manually fed by CMMS database downloads — just by using digital tools to harvest data from maintenance databases. Through analytics, you can upgrade your old FMEAs into powerful FMECAs.

The challenge of new machinery without available maintenance history can be overcome by using internal benchmark data from the CMMS’s global database of other manufacturing units. This is made available by integrating graphical resources and mathematical capabilities that any common business intelligence tools can now provide. Besides, with analytics’ fast learning curve, all these accomplishments can be done without major effort using internal labor resources (e.g., automation engineers, reliability engineers, etc.).

Modern RCFA Utilization

In any industrial sector, root cause analysis RCA

2 is a mandatory step for all companies seeking improvement to their processes. For some highly regulated sectors, such as pharmaceutical and biotechnology, root cause analysis (RCA) is more than improvement, it is a compliance requirement. For chemical industries or environments where process safety is a must, RCA effectively avoids the recurrence of issues, assuring people’s safety. The list of examples is huge when underlining the importance of RCA for any industrial players. It is, in fact, the most cost-effective way to avoid recurrent failures and, consequently, reducing maintenance costs. Thus, a good RCA program with a robust set of tools should be part of an organization’s strategy, included in its training and development plans, be part of its control strategies, and made compulsory for any business that pursues excellence for its processes.

Cross-functional teams, along with knowledgeable facilitators, enable the accurate identification of root and contributing causes, as well as ease the design of action plans to effectively mitigate or eliminate risks. When investigating failures, rare are the cases when just one root cause is found. Normally, several root causes or, at the minimum, a root cause along with its contributing causes are a common place at RCAs. In this context, it is important to remember that failures not addressed will result in bigger successive breaks and, consequently, high costs of reactive maintenance, downtime impact and potential regulatory threats to manufacturing processes.

However, with modern digital resources, available both on the equipment (e.g., a digital control system {DCS}) and in industrial network systems (e.g., inside a standard enterprise resource planning {ERP} system), an effective data collection with proactive usage through analytics tools can ease the investigation process. Audit trails of programmable logic controllers (PLCs) and DCSs are becoming more evolved each day, feeding investigations with traceable process information. CMMS work orders register fill gaps during RCA processes. Even surveillance systems have opportunities with registers to add information to RCA inquiries. The point is to use technology to empower your old ways to collect and process data for RCA purposes.

Investigating teams can use data from such digital sources to conduct more robust analysis, thus detailing failure investigations with distinct and rich perspectives over the failure scenario. These data can be used to provide inputs to RCA dedicated software or even to traditional tools, like fault tree analysis (FTA), Ishikawa diagram, etc. The combination of smart data with cross-functional teams provides better results and savings through more failure modes captured, less recurrence, and faster and more effectively deployed action plans.

Reliability Methodologies from Design to Maintenance & Operations

Good engineering methods, aligning modern and digital resources, can consistently improve and sustain efficient manufacturing processes. This learning was an important breakthrough for high-speed trains and aerospace manufacturers years ago. They have been using robust methodologies to assess and advance their products and installations.

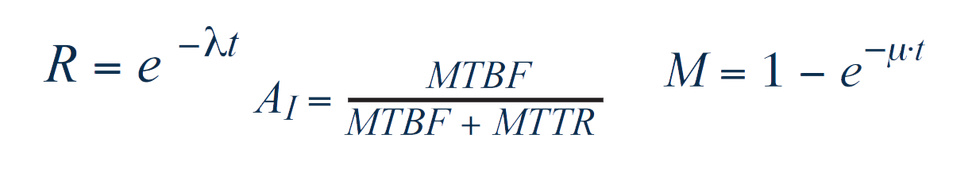

Among a big variety of options, one of the best is the reliability, availability, maintainability and safety (RAMS) methodology due to its robustness and low-cost implementation. RAMS can be deployed with very low investment by means of just some engineering equations

3 and through the usage of analytics resources to systematically automate calculations.

Figure 1: Reliability, inherent availability and maintainability equations

This approach, initially just for design and concentrated on specific niches like railway industry,

4 is nowadays spreading to other sectors as well. The railway industry is one of the pioneers using RAMS and it has progressively achieved impressive results, producing faster and safer high-speed trains every year.

Widely recognized as a key tool for the design phase, RAMS also can be deployed during any stage of the asset’s life cycle. Its expansion to maintenance programs has resulted in excellence for such manufacturers that is challenging archetypes and improving the reliability of operations and maintenance.5

Methodologies like RAMS can effectively contribute to the conversion of some intangible benefits of reliability into tangible gains, adding numbers to assumptions and insights about the asset’s health and equipment’s performance. RAMS and other asset management methods create the opportunities for cost savings by anticipating downtime caused by evolving failure modes in equipment and more effective decision-making capabilities for industrial investments.

Analytics to Speed up DDM Deployment

Data-driven maintenance (DDM) is a powerful method for maintenance cost reduction once it recognizes the use of data to drive maintenance decisions instead of relying on time-based inspections. Hence, besides a powerful ally of predictive techniques, it allows manufacturing processes improvements6 since decisions based on data and not just on insights are obviously more reliable.

Unfortunately, many companies do not benefit yet from their current maintenance history as they could because they are not aligning their approach in a database way. Through the application of AI algorithms, thousands of maintenance registers in a CMMS, like work orders, can be analyzed and, using pattern recognition, create many asset improvement opportunities in a similar way. Such an approach is being applied in operational optimization.

The way work orders are recorded and stored in the CMMS, the keywords used, the work duration, and many other parameters can be leveraged to boost maintenance savings when they are processed by AI algorithms, with the eyes of Industry 4.0. Such rich databases of asset information from your maintenance data can facilitate the redesign of systems and installations and revolutionize the way you maintain and even operate your equipment.

Figure 2: IIoT utilization leveraging gains and savings

Conclusion

Although the IIoT is rapidly evolving and spreading, there still may be a long way yet to go until appropriate levels of AI and machine learning are accessible, reliable and cost-effective enough for all industrial processes, mainly in more conservative and regulated industries.

However, the fast pace by which new technologies are growing and multiplying their applications to reduce costs, facilitate human adaptability and improve reliability, the much-anticipated benefits of Industry 4.0 may be closer than you think.

In this context, traditional engineering methodologies, supplemented by modern technologies and tools, such as analytics and business intelligence resources, must work together to speed up reliability, maintenance and operational excellence journeys inside the new digital arena.

With a risk-based approach, good control strategies and synergy between modern technologies and good traditional engineering methods, the Industry 4.0 crusade will continue its accelerated development curve, bringing breakthroughs that will change our lives and boost our evolution.

References

1. Administrative Assistant to the Secretary of the Army. “Army Publishing Directorate.”

TM 5-698-4: Failure Modes, Effects and Criticality Analysis (FMECA) for Command, Control, Communications, Computer, Intelligence, Surveillance, and Reconnaissance (C4ISR) Facilities. https://armypubs.army.mil/ProductMaps/PubForm/Details.aspx?PUB_ID=83559

2. International Electrotechnical Commission.

IEC 62740:2015 Root cause analysis (RCA). https://webstore.iec.ch/publication/21810

3. International Electrotechnical Commission.

IEC 61703:2016 Mathematical expressions for reliability, availability, maintainability and maintenance support terms. https://webstore.iec.ch/publication/25646

4. International Electrotechnical Commission.

IEC 62278:2002 Railway applications - Specification and demonstration of reliability, availability, maintainability and safety (RAMS). https://webstore.iec.ch/publication/6747

5. Tzanakakis K.

The Railway Track and Its Long Term Behaviour; Berlin/Heidelberg: Springer-Verlag: 2013.

6. Stoecker, C.

Data-Driven Predictive Analytics Can Transform Plant Engineering; Fall 2016 edition of Smart Manufacturing.

From Your Site Articles

Related Articles Around the Web