Seldom do railways have the resources to maintain their infrastructure at a level that ensures steady-state performance. Rather, they are faced with prioritizing maintenance actions to optimize safety and reliability under the burden of constrained resources. Given this reality, railway operations are finding the solution to work more efficiently lies in using information technology. By harnessing the vast amount of existing rail corridor data in a prioritized plan and then assigning the work and monitoring the execution and results with software, many railways are doing more with less resources. This strategy is called linear asset decision support (LADS) and it not only results in steady-state asset performance under constrained resources, it also can improve the asset condition and provide a positive return on investment.

The Challenge

Managing a reliable and safe rail corridor is typically performed with insufficient information and limited resources. Having simple to use and readily available asset location and condition information to prioritize the use of limited resources (e.g., people, materials, equipment and work windows) can dramatically affect the rail corridor’s reliability, safety and profitability.

Typical Rail Asset Data

A lack of data relating to a rail asset is rarely an issue for rail operators. Around the world, vehicles measuring multiple aspects of the network routinely collect gigabytes of data. The issue is not, “Do we have the data?” but “What do we do with it now that we have it?” Rail data is often stored in multiple, disparate silos, with little or no ability to view these data sets together.

Data Issues

Rail measurements are also prone to errors of various types:

- Location errors that occur when a feature recorded against the track is in the wrong location;

- Flat lines and spikes;

- Calibration errors that occur when the data recorded is incorrect because calibration settings used to convert raw measurements into usable data are incorrect;

- Filter warm-up errors occur when the first piece of data in a recording or after a gap within a recording is not valid because filters used to derive it take time to generate valid data;

- Environmental issues (e.g., sunlight can blind optical systems) and many measurement devices are sensitive to temperature, moisture, or vibration;

- Low speed issues (e.g., accelerometers are less accurate at lower speeds) and some instrumentation (e.g., laser scanners) might need to be set to disable automatically at lower speeds for safety reasons;

- Deterioration of instrumentation: the instruments used are measuring in a harsh environment and are prone to knocks and dirt.

Typical Recordings

Track Geometry

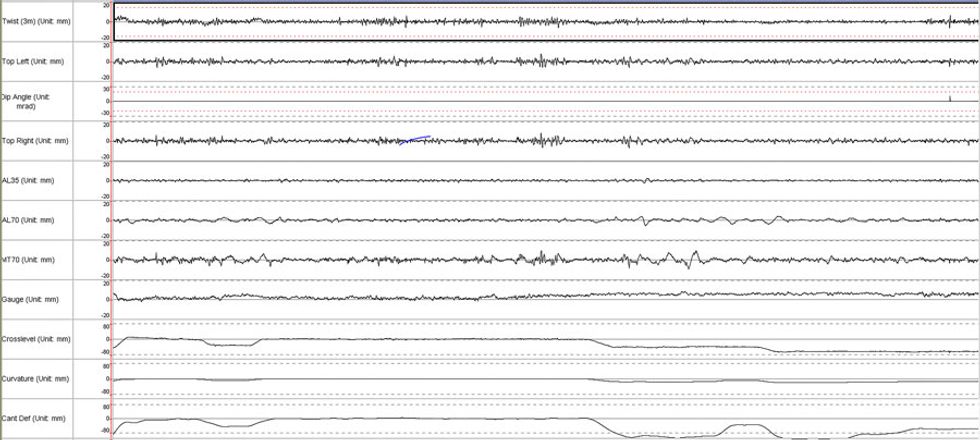

Track geometry is a description of the location of the tracks in space. Rather than exact X and Y coordinates, engineers are more interested in the variation of the geometry along the track. Items, such as unevenness in the geometry of the rail or variation in the gauge between rails, can cause ride discomfort and increase the risk of derailment.

Figure 1: Typical track geometry data visualization

Rail Profile

Rail profile is a measure of the wear on the top and side of the rail. Trending this data helps determine where the rail is approaching the end of its lifecycle and whether it needs replacing.

Traction Power: Overhead Line and Conductor Rail

Traction power comes in two variants: overhead line and conductor rail. Overhead line is generally a high-voltage alternating current (AC) system suspended above the track. Conductor rail is usually a low-voltage direct current (DC) system with more current.

Asset Location and Attributes

Data relating to asset locations and asset attributes is recorded for information, such as the location and age of the rails, as well as for related assets, such as bridges, stations and switches. This data set should provide all the information required to define the linear referencing system for the railway. Any asset that may influence maintenance or renewal decisions should be included.

Maintenance Records: Historic and Planned

Historic maintenance records should be included for several reasons:

- To allow assessment of the effectiveness of historic maintenance actions;

- To ensure trends in deterioration take into account maintenance that has taken place;

- As a record to allow best practices to be understood and communicated throughout the workforce.

Planned maintenance activities should be included to compare them to the predicted future state of the network.

Ultrasonic

Ultrasonic data allows engineers to look inside rails in a nondestructive manner.

Video

When video is synchronized against all other data sets, it provides context as to what is happening around the assets.

Typical Forms of Analysis

There are a number of standard forms of analysis. While the details may vary according to vehicle types, line speeds and units used, the principles are constant for most rail networks.

Alignment

As mentioned previously, measurement data suffers from a number of issues that can prevent optimal decision-making. One of the key issues is the accuracy and reproducibility of the location system used with the measurement system.

For rail measurement data, accuracy and reproducibility are defined as:

- Accuracy: How well can the location be identified in the real world?

- Reproducibility: If the same feature is recorded multiple times, how close together are they reported?

This distinction is important, as a systematic location error would make data reproducible, but not accurate. For example, if there is always a 20-meter error in the reported location of a fault, but the data is highly reproducible, then a fault will be reported repeatedly at exactly the same location. However, the reported location is 20 meters away from where the fault lies in the real world.

Data Cleansing and Validation

As noted previously, data can suffer from numerous issues. The most common of these are spikes and flat lines. Each can be relatively easy to handle provided that care is taken not to remove valid data.

Figure 2: Track geometry data before and after validation and alignment

Segmentation

Segmentation is the logical “cutting up” of the track network into lengths of track that can be analyzed separately. This is done for a number of reasons:

- To group together similar lengths of track;

- Some channels require a calculation of the variance of the channel over a length to derive a track quality index;

- To visualize track condition more easily;

- To report maintenance requirements in manageable lengths of track.

Segments are normally chosen based on what they need to represent and how they are going to be calculated.

Quality Index Generation

Once data has been aligned and cleansed, and an appropriate segmentation has been defined to apply quality indexes, quality indexes can be generated.

A quality index is a function applied to measurement data over a segment that represents the quality of the asset within that segment.

The value of a quality index should be capable of being affected by certain classes of maintenance. The index should be used as a measure for what the state of the asset is and how effective maintenance has been.

Thresholding

As well as defining track quality indexes, network maintainers need to know if there are any localized issues in the network that require attention. This is determined by taking track geometry measurements and applying thresholds to them.

Trending

Trends are mathematical functions that can be used to estimate future values of track quality indexes.

There are two basic mechanisms for trending future values of data:

- Extrapolation from observations – Where multiple measures of a track quality index have been derived, a best fit line can be drawn through the data and then extended into the future.

- Applying a mathematical prediction to the most recent observation – Where insufficient data exists to produce a best fit based on observations, it becomes necessary to predict values based on a theoretical model.

Prediction

Once a trend function has been derived from aligned and cleansed data, future values can be predicted.

There are normally several key condition values that need to be tracked. They are failure starts, potential failure, functionally failed and broken. These values are derived from either thresholding measurements or deriving quality indexes.

Figure 3: Names of key dates in the deterioration of an asset

Other Uses for Data Measurement

Validation of Maintenance Effectiveness

Analysis of asset condition before and after maintenance can be used to derive the effectiveness of maintenance.

Asset deterioration typically looks like a sawtooth diagram, where the asset condition (Y-axis, where higher values equals worse condition) deteriorates over time (X-axis, most recent date to the right).

Figure 4: Asset deterioration including a maintenance event

Track Recording Coverage

Most rail operators have required monitoring intervals for tracks. These intervals are usually based on line speed or track criticality, with the fastest and most critical tracks monitored more frequently. The actual interval can be derived from the measurement data and then compared to the schedule to ensure inspections adhere to the required standards.

Conclusion

While track measurement data needs to be treated carefully to understand its limitations, it contains a wealth of information that can benefit maintenance and renewal maintenance engineers. Using software applications that place the focus on the analysis and forecasting of data trends, engineers are able to make better informed decisions about maintenance, renewals and life extensions. From detecting errors in imported data, deriving statistics and exceedances from measurement data, and predicting deterioration, these predictive analytical tools will be critical for success as the rail industry continues to expand at an increasing rate.

Rail asset managers should take note. Prepare for the challenges that lie ahead and turn them into competitive advantages. Include LADS in your rail infrastructure asset management strategy. The result will be steady-state asset performance, even under constrained resources, reliability and safety, at the lowest possible cost and a positive return on investment.