Asset criticality is a ranking of assets according to potential operational impact. This is usually determined through a formal asset criticality analysis on each asset or group of like assets.

The analysis is based on agreed upon criteria, such as safety, environmental and quality risks; operational impact (e.g., supply chain, demand, profitability, etc.), mission impact, maintenance and reliability impact (e.g., consequence and severity of failure), level of redundancy, asset replacement cost, spare lead time, or any other factor important to an organization.

Criticality supports prioritization of assets that are important to monitor and should be maintained at an agreed upon level of maintenance based on the consequences of failure.

A well-defined asset criticality analysis helps to improve:

- Capital projects and sustainment planning

- Maintenance optimization

- Work order prioritization

- Cost avoidance metrics

STEP 1

Define the Scope

Define which assets will receive criticality analysis and which will not. All assets may not benefit from a formal analysis. For example, it may be advantageous to limit the scope to only assets with an active preventive maintenance plan, only assets owned by a particular organization or contained in buildings of higher importance, or only assets of a particular type, such as building assets and not vehicles. Once the number of assets is settled, the time for completion needs to be agreed upon. Completion time depends on several factors: How in depth the scoring will be, how many staff hours can be dedicated to the effort, how experienced the team is, etc. As a very rough estimate of time, you can assume it will take one minute of time per asset.

The first step relies on the integrity of your asset registry. An asset registry is a list of all assets that may be stored in a computerized maintenance management system (CMMS) or in a spreadsheet. If your organization does not have a registry and merely maintains equipment as it breaks down, a list will need to first be created. Similarly, a registry may exist, but is so outdated/incorrect that it is unusable. To create/correct an asset registry, each asset needs to be logged, either in person or using reliable reference material such as building drawings. This is also a good time to capture information necessary to perform the criticality assessment, such as nameplate data and equipment configuration.

STEP 2

Form a Team

Determine the stakeholders for criticality, then hold regular meetings to confirm the rating. All positions could be from within an organization if self-performing, or, if applicable, a mix of contractors and organization members.

A typical team consists of a:

- Criticality Leader – This person is the leader of the effort, driving the project through completion. Responsibilities include coordinating regular meetings, updating the spreadsheet or whatever tool is used, collecting information vital to the analysis, and putting the first pass of a score on each asset.

- Asset Owner – The owner or representative of the asset owner who typically has the heaviest weight on the final asset criticality score.

- Subject Matter Expert – An individual who best understands the function of the asset and how it is related to other equipment. Typically, the responsible maintenance technician (i.e., the person who fixes the asset when it’s broken), maintenance supervisor, operator, or someone who has just been around for a long time and knows the assets, can fill this role. This individual will likely rotate depending on what group of assets are being looked at.

- Safety – An individual who is or can act as the safety representative in a maintenance organization. This person should seek to give extra consideration to assets failures that pose a life safety hazard.

- Planner/Scheduler/Production Control (optional) – This individual or team performs planning, scheduling and jointly manages the CMMS system. These people typically have a strong understanding of asset configurations and provide great value to the criticality scoring team. They can also advise on how best to integrate the score into the CMMS.

- Executive Sponsor (optional) – This individual can help direct resources to the project and has an interest in its success. The resources may be financial and/or personnel related.

STEP 3

Define Criteria

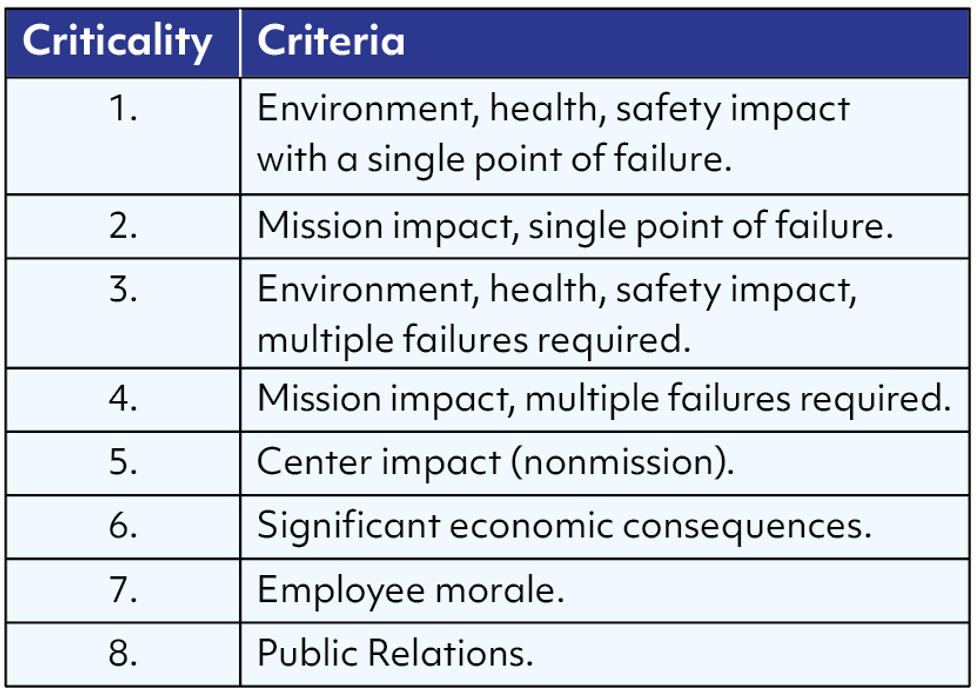

How to score each asset needs to be defined by the group. Presented here are three criteria examples that can be referenced and modified to best fit the facility being analyzed. The team must define and agree on a criticality ranking process that is valuable, usable, and understandable to all stakeholders. An example is the criticality method outlined in the NASA Procedural Requirements, NPR8831.2F. The criteria table is shown in Figure 1.

Figure 1: One criticality criteria example is NASA’s NPR8831.2F

Figure 1: One criticality criteria example is NASA’s NPR8831.2F

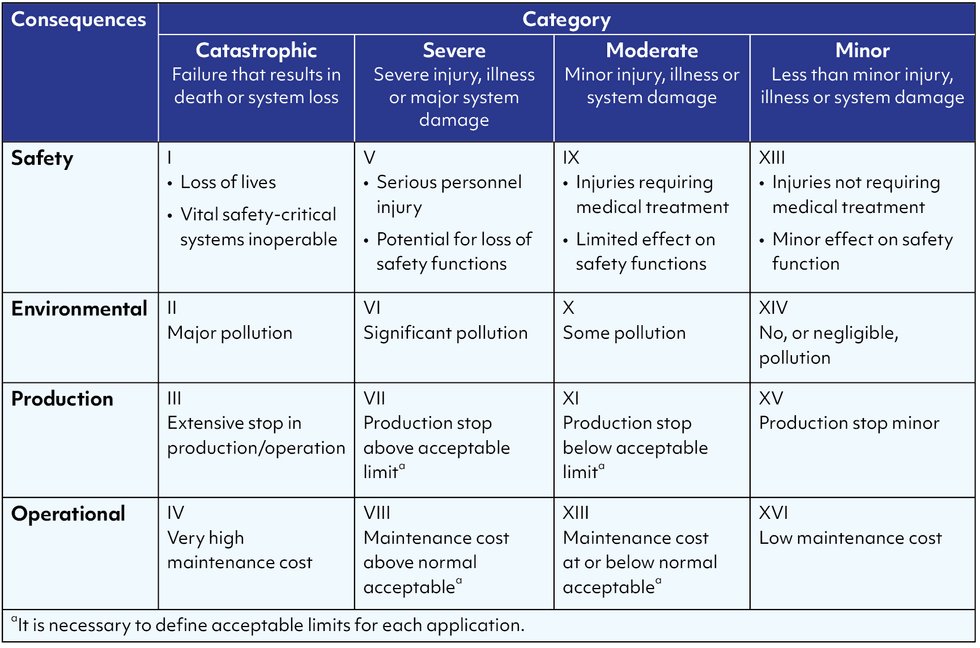

Another popular and simple scoring system is High, Medium, Low. ISO14224: Petroleum, petrochemical and natural gas industries — Collection and exchange of reliability and maintenance data for equipment has a failure consequence block, provided in Figure 2, that can be used to score assets. Using the table in Figure 2, High could be reserved for quadrants I, II and V, Low reserved for quadrants XII, XV and XVI and Medium would represent the remaining quadrants.

Figure 2: A high, medium, low criticality criteria example from ISO14224

Figure 2: A high, medium, low criticality criteria example from ISO14224

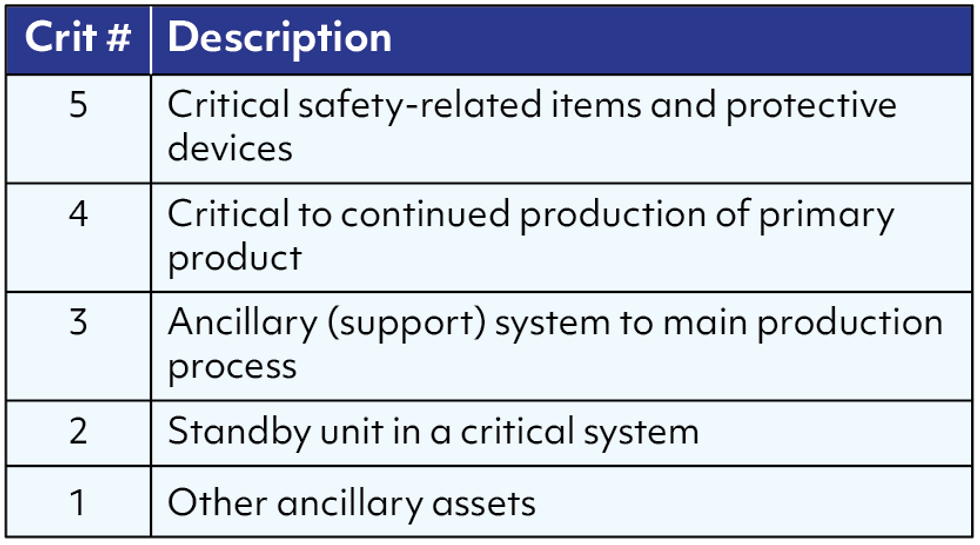

Finally, a simplified 1 through 5 asset criticality referenced in the book,

Asset Maintenance and Reliability Best Practices, 3rd Edition by Ramesh Gulati, is provided in Figure 3.

Figure 3: A 1-5 criticality criteria example from Asset Maintenance and Reliability Best Practices

Figure 3: A 1-5 criticality criteria example from Asset Maintenance and Reliability Best Practices

STEP 4

Grouping and Scoring

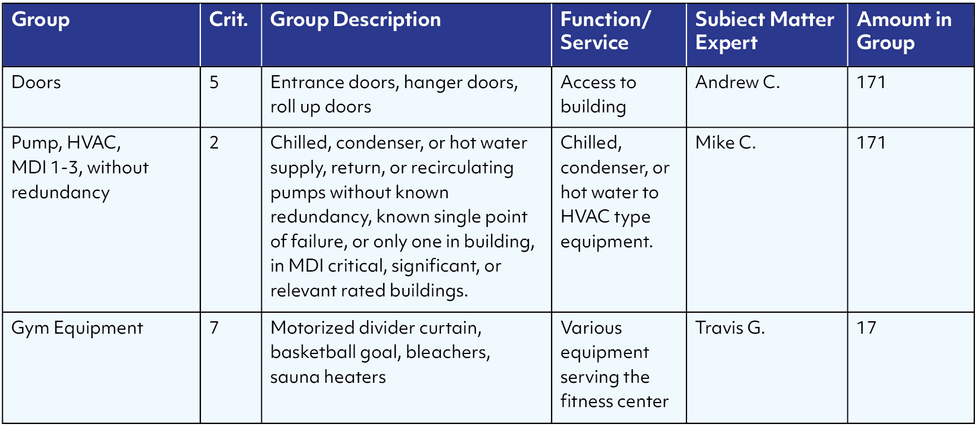

Scoring assets individually can be a time-consuming process if there are a significant number of assets. Instead of scoring each one, similar assets can be assigned to a group and that group can be scored. For example, all the fire alarm panels for a building could be lumped into a single group and given the same score. Groups of assets should share the same service and consequences of failure.

When starting to score assets, the ones that are obviously critical or obviously noncritical are easier to begin with as the team becomes familiar with their scoring criteria and the scoring process. These are typically life safety systems and equipment directly serving the goals of an organization. Noncritical equipment examples include bathroom exhaust fans, kitchen equipment, drinking fountains, etc. Using this method, approximately half of your assets can be quickly grouped and scored and allow the team to make some early progress.

The other half of your assets are typically for equipment with hard to define service areas. Think about electrical panels. For a large site, there could be thousands of electrical panels, the services of which are not exactly known without going through thousands of schedules and drawings. For these, it can be helpful to define how critical the individual buildings or rooms are, then determine which assets serve those spaces. For example, the consequences of failure for HVAC systems in more critical buildings would be higher than a similar system in a less critical building.

An example spreadsheet for grouping and scoring is provided in Figure 4. In a separate tab of the spreadsheet, each asset would be assigned its relevant group.

Figure 4: Grouping and scoring spreadsheet example

Figure 4: Grouping and scoring spreadsheet example

STEP 5

Meet Regularly

The criticality leader should regularly go through the assets on the list and assign a temporary criticality number using the agreed upon method. Assuming the tool used to track criticality is a spreadsheet computer program, the temporary number would be highlighted yellow to indicate its temporary status. During the meeting, the leader would then present the recommended number to the stakeholders. The number would be approved or changed, then updated to green to indicate a complete status. If the number is not agreed upon or more information is needed, the color remains yellow and is brought up again at the next meeting. The subject matter expert generally rotates, as a new expert is asked to join depending on what asset category is on the agenda. For example, if the agenda for the week lists plumbing assets, it would be helpful to invite the plumber who maintains them. By repeating this process, all assets will receive an approved rating and the team can more easily report on progress and estimate time until completion.

STEP 6

Updating the Asset Registry

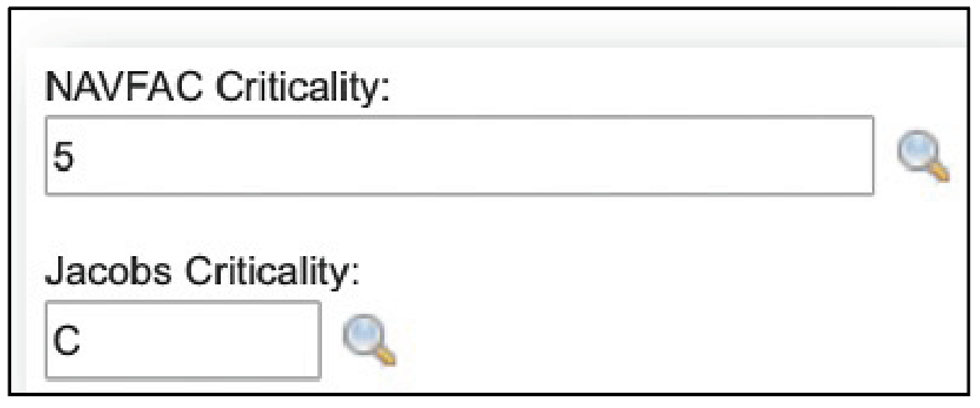

The final scoring should be placed back into the asset registry or CMMS database. If using enterprise asset management (EAM) software, some have a built-in “priority” field that can be utilized. Alternatively, the “priority” display name can be changed to criticality or a new field can be added. It is best to rely on the expertise of the team’s optional Planner/Scheduler/Production Control Person on how best to update the system.

Once the information is properly stored in the maintenance database, it is a good time to provide training to the staff who may not have been involved in the scoring process. They will need to know the benefits of having an accurately scored asset criticality, the scoring criteria, how it applies to their work, and how to properly submit corrections. The tool used for scoring can now become a tool for training.

Figure 5: An example of two custom fields on an EAM system

Figure 5: An example of two custom fields on an EAM system

STEP 7

Continual Improvement

Criticality is a snapshot of the estimated importance each asset is to an organization at the time it was calculated. As the mission changes, technology changes, and even the asset changes, the criticality will no longer be as accurate. How and when the next update should be are dependent on the needs of each organization. Here are some questions to ask to help answer how best to continually improve:

- How well is the existing criticality being utilized?

- How much has changed since the analysis?

- Is the existing criticality being regularly updated?

- Are new assets being scored as they are installed?

- What assets do not have a criticality score?

Figure 1: One criticality criteria example is NASA’s NPR8831.2F

Figure 1: One criticality criteria example is NASA’s NPR8831.2F  Figure 2: A high, medium, low criticality criteria example from ISO14224

Figure 2: A high, medium, low criticality criteria example from ISO14224  Figure 3: A 1-5 criticality criteria example from Asset Maintenance and Reliability Best Practices

Figure 3: A 1-5 criticality criteria example from Asset Maintenance and Reliability Best Practices Figure 4: Grouping and scoring spreadsheet example

Figure 4: Grouping and scoring spreadsheet example  Figure 5: An example of two custom fields on an EAM system

Figure 5: An example of two custom fields on an EAM system