What is Asset Condition Assessment?

Asset condition assessment (ACA), asset health index (AHI), and assetremaining life (RL) all have the same essence, and all share a common goal: toassess and measure the condition of an asset in terms of physical degradation,loss of performance, and obsolescence. While they may differ in specific detailsand methodologies, they all aim to assess the overall condition of an asset (ISO-55000).

Step 1: Organization of an Asset Condition Assessment Situation

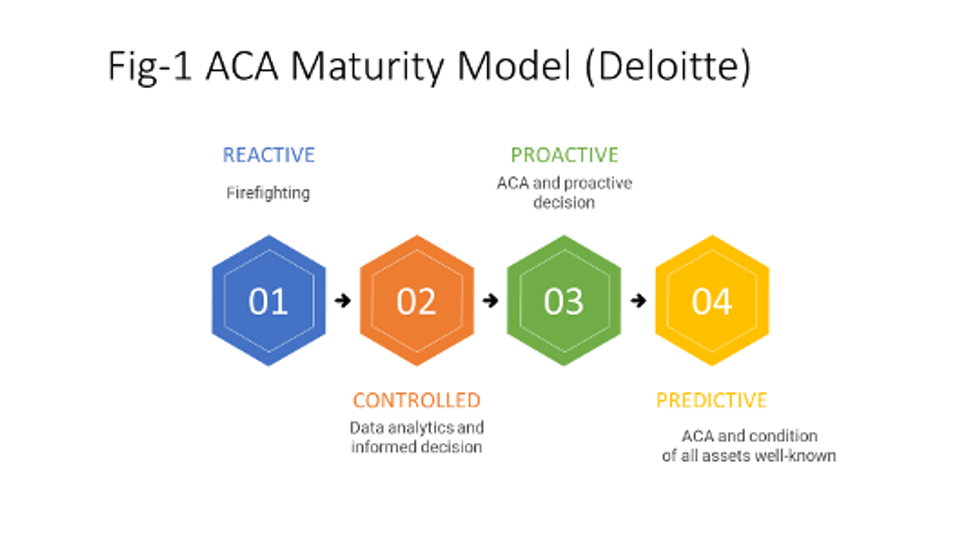

The current state of an organization’s asset management can be categorizedinto four stages (Fig-1) (Deloitte-CEA):

- Reactive stage: The organization is in firefighting mode. They areoverwhelmed by failures and breakdowns.

- Controlled stage: Operations, maintenance, and QAQC data are collectedand analysed for informed decision-making.

- Proactive stage: The organization has a robust asset conditionassessment system. They are using data to make proactive decisions.

- Predictive stage: This is the ultimate situation where the conditions of allassets are well-known, and the organization uses asset conditionassessment data and analytics to predict and prevent issues before they occur.

The asset condition assessment journey (Fig-2) can be adapted to suit theorganization’s needs and requirements.

Step 2: Resources to Perform Asset Condition Assessment

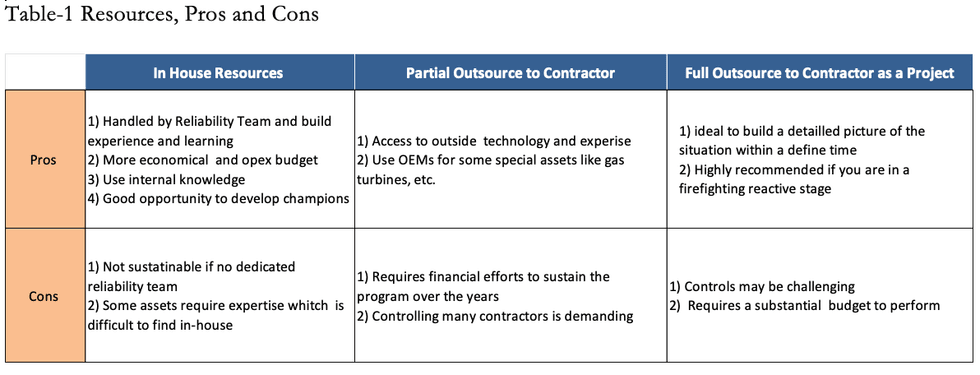

The organization has to decide if the asset condition assessment will be fully outsourced, partially outsourced, or if it will be carried out using in-house resources. Table-1 gives the pros and cons of the three options.

Step 3: Develop an Asset Register

An asset register is a centralized record of the inventory of the organization’sassets. It can be prepared on a spreadsheet or generated as a report in acomputerized maintenance management system (CMMS). The data should be ascomprehensive as possible. Assets should be grouped by area, type, vendor,systems, or by criticality—depending on the facility and requirements.

Step 4: Asset Condition Assessment Prioritization

Before starting the asset condition assessment process, it is recommended toprioritize which assets to assess first. A reasonable approach is to plan thereview in phases. Start by targeting groups of assets based on their criticalityand impact on safety and operations, their condition in terms of poor reliabilityand performance, and their age.

Step 5: Data Gathering

Existing data: Organizations collect all sorts of data—from operationslog sheets to DCS data, QAQC inspection, maintenance, reliabilityreports, computerized maintenance management systems, and more. This is thetime to harvest this information for the asset condition assessment. The core approach focuses on the following data:

- QAQC Reports: The inspection reports issued by the QAQC department canbe collected and reviewed to gather important information and data andtrend over time.

- CMMS data: The data may be generated through reports on the differenttypes of WOs whether preventive maintenance, corrective maintenance, orbreakdown maintenance over 5-10 years period, with failure codes, man-hours, lead crafts, and rework.

- Operations log sheet: The data on the log sheets will help trend processvalues that are of interest. The log sheets will also have data on assets inservice, or on stand-by, or under maintenance.

Generate additional data: Once the existing data have been collected, theneed may arise for additional data to ascertain the condition of the assets. Mainly:

- On-site performance test: This type of test is carried out on assets likerotating equipment, electrical motor, packages, etc. to demonstrate that thecondition of the assets is meeting or not the design specifications andstandards in terms of process, mechanical and overall efficiency.

- Condition monitoring data: The techniques for condition monitoring entailthe monitoring of assets depending on the type through vibration, lube oilanalysis, acoustic emissions, and thermography.

- Obsolescence studies: The obsolescence study aims to determine wherethe asset is in its lifecycle, when the asset is technically or commerciallyobsolete, and when the availability of spare parts and services will bediscontinued.

- Health check test: This is a comprehensive test that encompasses all theabove tests and is normally performed by specialized contractors or OEMson certain types of assets like rotating equipment, oil-filled transformers,HV-MV cables, etc.

Step 6: Data Analysis

The data collected should be analyzed to generate information and keyperformance indicators (KPIs) to trend and assess the condition of the assets.The analysis uses various tools and techniques to:

- Determine the corrosion rate with the percentage of metal loss.

- Build the asset failure history using root cause analysis.

- Use data to generate metrics such as asset reliability, availability, failure rates, mean team between failures, and mean time to repair.

- Develop a total ownership cost for critical and expensive assets.

- Enquire about spares availability for the next 5-10 years and the asset obsolescence cycle.

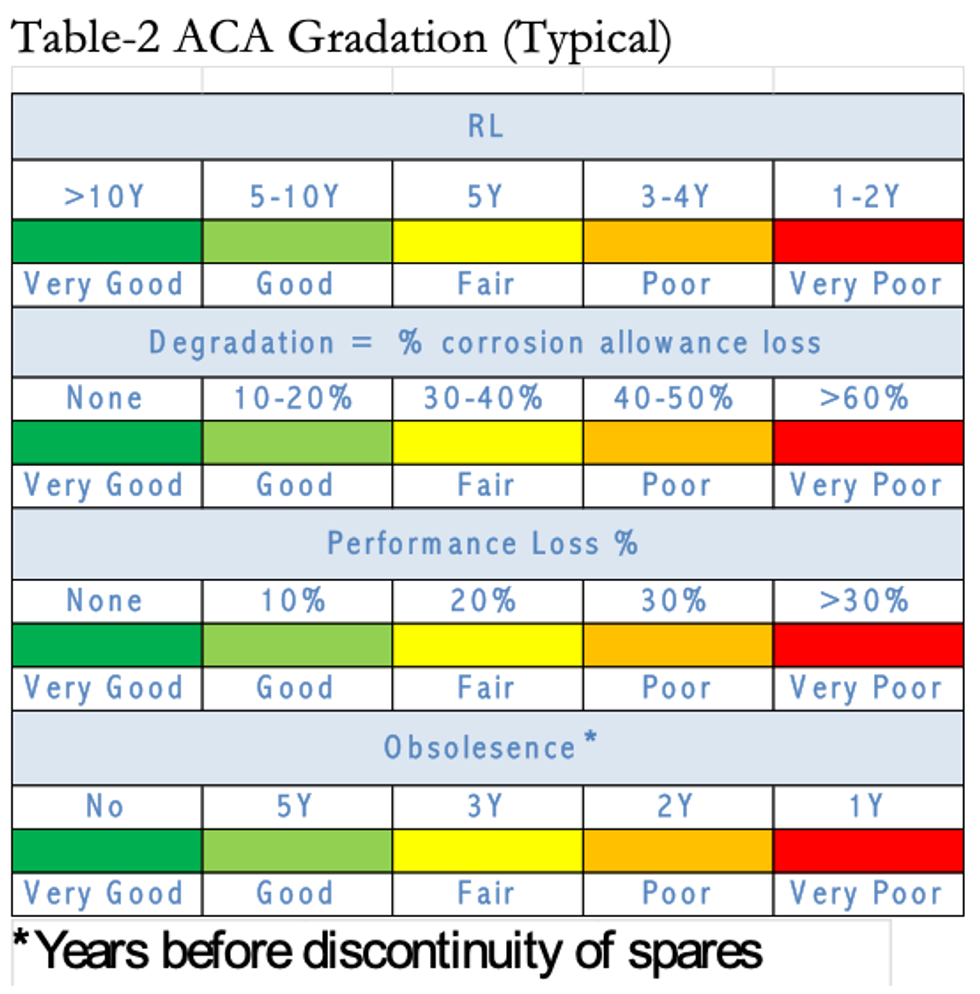

The asset condition assessment should at any given time give KPIs, data, andinformation about the asset to determine the asset remaining life. Table-2 givesa typical gradation that can be referred to.

Risk assessment: The assets in poor condition may pose a challenge to safety,health, and operations, and should be subjected to risk assessments with theobjective to ensure that potential risks are identified and mitigated.

Step 7: Asset Condition Assessment Outcomes and Recommendations

The outcome of the asset condition assessment should be a formal report (Fig-3)covering the history, present condition, and desired condition of the asset. The report will include recommendations and actions that should be put in place in the short, medium, and long term to reach the desired conditions.

Conclusion

It is essential to view the asset condition assessment as an integral part of anorganization's integrity systems, anchored in considerations of safety, risk, andoperational requirements. By taking this methodical approach, organizationscan gradually build and enhance their asset condition assessment process andtheir decision-making capabilities through evidence-based information, and datain order to optimize the maintenance and longevity of their assets, predictpotential issues, and prioritize asset life extension projects.

References

(1) ISO 55000 (2014) Asset management, overview, principals, and terminology

(2) Deloitte/Canadian Electricity Association. (2014). Asset health indices: Autility industry necessity maturity model