In today’s fast-paced manufacturing landscape, managing spare parts inventories efficiently is critical to ensuring uninterrupted production. As industries strive to maintain the delicate balance between stocking adequate spare parts and controlling costs, traditional methods often fall short in addressing the dynamic demands of modern manufacturing. These conventional approaches, primarily based on static algorithms, struggle to adapt to evolving production needs, leading to either overstocking or stockouts and ultimately inefficient maintenance practices.

This article introduces an optimized spare parts management framework using a spare part criticality tool that considers critical factors, such as asset criticality, lead time, failure frequency, and supply chain dynamics, to ensure a reliable and cost-effective spare parts strategy.

To address gaps in existing tools, the spare part criticality tool creates a dynamic spare parts optimization model to incorporate changing lead times, failure patterns, asset criticality, and global stocking strategies. The proposed approach not only reduces operational costs, but also enhances supply chain reliability, streamlining the availability of essential components without overburdening inventories. It integrates maintenance and supply chain metrics to create a more adaptable and efficient system, demonstrated through case studies that reveal significant cost savings and improved operational efficiency.

Methods and Materials

In manufacturing, timely spare parts availability is vital to avoid production disruptions and maintain optimal equipment performance. Spare parts forecasting, based on critical factors, such as failure frequency, lead time, and usage patterns, is essential for anticipating demand and minimizing inventory costs. This process is complemented by inventory control, which establishes optimal stock levels and reorder points to extend the lifespan and reliability of spare parts.

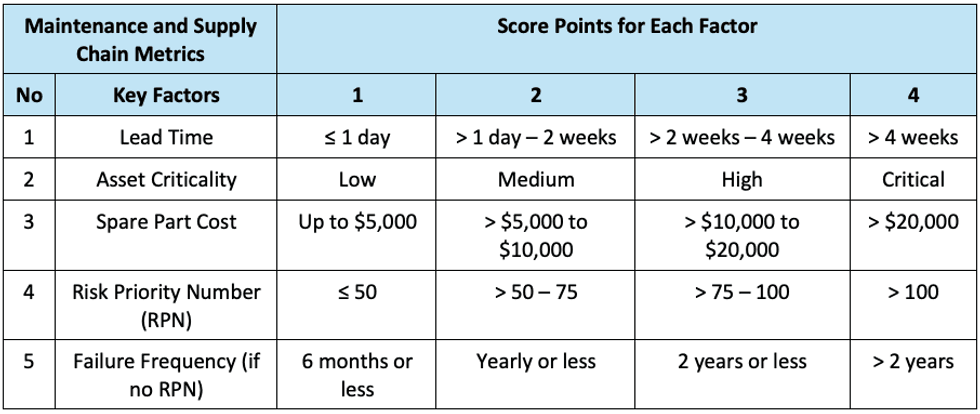

Table 1 – Key factors with score points

Table 1 – Key factors with score points

Several key factors influence the criticality of spare parts, including lead time, asset criticality, spare part cost, and failure frequency. For organizations that lack failure data, failure frequency estimates, drawn from manufacturers’ data and field experience, can serve as a reliable proxy for predictive stocking. Additional factors, such as the unique nature of custom parts, the mechanical or nonmechanical classification of parts, inventory holding costs, and lifecycle stages, also play a critical role in determining appropriate stocking levels.

Table 2 – Additional factors with score points per Industry need

Table 2 – Additional factors with score points per Industry need

Table 3 – Stock quantity as per part criticality

Table 3 – Stock quantity as per part criticality

To address the complexities of spare parts management, a simple, spreadsheet-based tool was developed that consolidates these factors into an actionable framework for determining spare part criticality and stocking levels. This tool enables organizations to prioritize spare parts based on operational needs, ensuring efficient resource allocation and minimizing production downtime.

Global Stocking of Spare Parts

For organizations with multiple facilities, expanding the spare parts management strategy to include global stocking considerations offers substantial advantages. By integrating factors, such as lead time, spare part criticality, inventory levels, and transfer costs, the framework enables organizations to make strategic decisions about which parts should be stocked globally versus locally. This global perspective optimizes inventory levels and ensures critical parts are available when and where they are needed most, reducing the risk of supply chain disruptions and minimizing operational downtime.

The following two case studies show the spare part criticality tool in action.

Case Study #1

A high-paced manufacturing organization faces substantial challenges in spare parts management due to poor documentation, disorganized storage, and a large inventory of obsolete parts.

By implementing the spare part criticality tool, the organization was able to achieve over million in annual savings through improved inventory management, minimized downtime, and optimized procurement processes. This approach allowed the organization to categorize parts by their importance and usage, leading to more informed stocking decisions and greater overall efficiency.

Case Study #2

A newly constructed manufacturing unit faced challenges in determining appropriate stocking levels for new equipment, as the facility lacked historical failure data. By leveraging industry data and applying the spare part criticality tool, the organization was able to reduce its initial spare parts procurement costs to half. The tool also identified opportunities for global stocking, presenting significant potential savings. This case study demonstrates the tool's ability to reduce costs and ensure efficient spare parts management, even in newly built manufacturing environments with limited historical data.

Results

The two case studies demonstrate the application of the spare parts criticality tool in real-world settings.

Figure 1: Scores for spare criticality assessment

Figure 1: Scores for spare criticality assessment

The addition of the spare part criticality tool in a spare parts management framework addresses several shortcomings of traditional methods by incorporating dynamic factors, such as evolving lead times, failure patterns, and supply chain considerations. Traditional methods often rely on static algorithms or empirical formulas, failing to account for the complexities of modern manufacturing, such as changes in failure rates or the unique requirements of custom or obsolete parts. By contrast, using a dynamic, data-driven approach leverages real-time plant data to forecast spare parts needs more accurately and proactively.

Both case studies reveal the potential cost savings and operational improvements achievable through this approach. The first case study demonstrates how the tool can address obsolescence issues, with savings projected to increase over time as the organization continues to refine its spare parts management practices. In the second case study, the tool effectively reduced spare parts costs for a new manufacturing unit while also facilitating global stocking strategies that enhanced supply chain resilience.

In comparison to previous studies, this article introduces the concept of dynamically adjusting spare parts stocking levels based on real-time data from plant operations, as well as integrating a global perspective on stocking. Previous research often overlooked these factors, relying instead on static models that failed to adapt to changing manufacturing conditions. The new approach addresses these gaps, offering a more comprehensive and flexible framework for spare parts management.

Conclusion

Efficient spare parts management is crucial for modern manufacturing operations to avoid costly production disruptions. Traditional approaches often fail to adapt to the dynamic needs of today’s industries, leading to suboptimal inventory levels and inefficient maintenance practices. Instead, a comprehensive framework for spare parts optimization integrates maintenance and supply chain considerations to ensure timely availability and optimal stocking levels. By leveraging a dynamic assessment tool, organizations can streamline their spare parts management processes, reduce costs, and enhance operational efficiency.

Additionally, organizations with multiple facilities can benefit from global stocking strategies, which optimize inventory levels across sites, reduce the risk of supply chain disruptions, and further improve cost-effectiveness. The case studies presented in this article demonstrate the real-world applicability of the proposed approach, highlighting significant savings and operational improvements. Future research may expand the scope to include consumable items, which have unique challenges related to fluctuating demand and widespread use.

Ultimately, the new approach offers a valuable tool for organizations seeking to improve their spare parts management practices, ensure operational resilience, and achieve long-term cost savings.

Disclaimer

The views and opinions expressed in this article are solely those of the author, drawn from over two decades of industry experience in reliability, maintenance, and project engineering, and do not represent the official policy or position of any current or former employer. The methods and examples described are based on generalized industry practices and do not disclose any proprietary, confidential, or company-specific information.

Table 1 – Key factors with score points

Table 1 – Key factors with score points Table 2 – Additional factors with score points per Industry need

Table 2 – Additional factors with score points per Industry need Table 3 – Stock quantity as per part criticality

Table 3 – Stock quantity as per part criticality Figure 1: Scores for spare criticality assessment

Figure 1: Scores for spare criticality assessment