Traditionally, reliability engineers have been the leaders in introducing new maintenance processes and technologies. As the primary owners of asset reliability, whether or not it came from the introduction of condition-based maintenance or instrumentation, they have been at the core of the transformation.

With the start of predictive maintenance, many other branches of the organization will become part of the process; at a minimum, there will be strong IT involvement and involvement of the chief operating officer (COO) or vice president of operations. Furthermore, companies might have an Internet of Things (IoT) strategy unit, a digital unit, or an analytics center, all of which will be interested in the rollout of predictive maintenance.

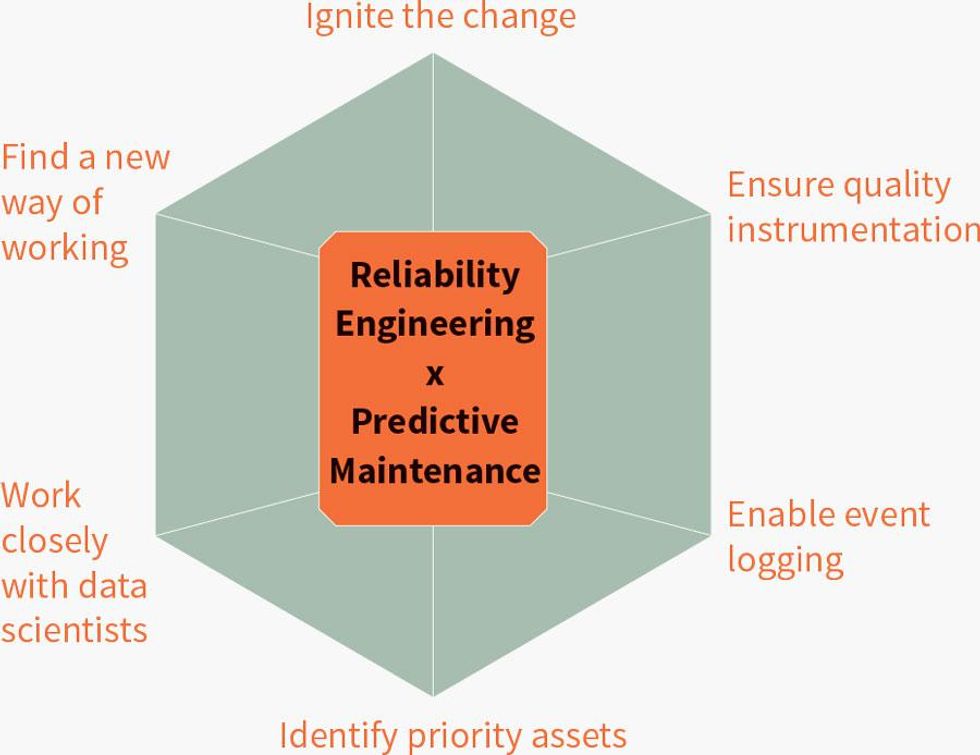

Despite these forces and the excitement at all levels of the organization, reliability engineers should strive to remain at the center of this transformation. This article presents some practical ways on how they can get involved.

Figure 1: A Journey Toward Wireless Asset Condition Monitoring

Figure 1: A Journey Toward Wireless Asset Condition Monitoring

Ignite the Change

The McKinsey Global Institute estimates that predictive maintenance solutions will have a potential impact of nearly $630 billion per year in 2025 in manufacturing alone. This level of reduction in equipment downtime and equipment capital investment should be very attractive to reliability engineers who can recommend exploring predictive maintenance and recruit other parts of the organization to provide the necessary level of support.

First, it is important to communicate the potential return on investment (ROI) to the organization. Reliability engineers have significant opportunities either in uptime and/or equipment capital investment that can be addressed using data and predictive maintenance.

Second, it is important to understand that this ROI can be phased in through small rollouts and experiments. By trying small pilots on critical equipment, the potential impact can be proven cheaply and only then transitioned into a broader program.

Third, the IT and analytics organization can be reassured that their capabilities might need to grow in this process and there are many external consultants who can help. Some major consultancies provide end-to-end analytics services that cover predictive maintenance and many other operations usage cases. It is a great starting point for industrial companies to increase their digital competency.

Ensure Quality Instrumentation

It should not come as a surprise that data is the cornerstone. For predictive maintenance to work, critical equipment needs to be comprehensively instrumented with sensors. These sensors, in turn, should be connected to a central and structured data collection facility (i.e., the historian).

Here is a good test for determining whether the right sensors have been used: Can the reliability engineer use a complete extract of data being collected automatically to build an informed picture of asset health? If so, there is hope in transferring this knowledge into the predictive maintenance algorithm and applying it at a much larger scale across the complete set of sensors.

If there are critical sensor readings that are only collected manually or available in a fragmented fashion across multiple systems, using them for predictive maintenance will be challenging, but still possible.

Enable Event Logging

By figuring out how to introduce more automation in data collection, valuable data sources can be established from which predictive maintenance systems can directly benefit. Counterintuitively, knowing 100 instances of past failures can be more important than having terabytes of sensor readings.

If data is sitting around in spreadsheets or e-mail, it would be useful to start capturing it in your maintenance system. Downtimes, failures and repairs should be logged, tagged and described. Missing out on critical events or not labeling them correctly reduces the value potential of predictive maintenance.

Identify Priority Assets

Predictive maintenance needs to be rolled out in a controlled and asset-by-asset fashion. Thus, selecting where to start and how to prioritize is important. Reliability engineers should provide input when assessing which data is relevant, which asset classes behave in a predictable way, as well as where opportunities for downtime or investment reduction are the greatest.

Work Closely with Data Scientists

It is likely that data scientists will be involved in constructing predictive models based on past data. They will be looking to join up, clean and structure data sets and then reveal and exploit hidden correlations.

It is tempting to see this process as a black box, whereby a standard set of techniques will reveal additional insight and replace human reasoning. However, it is the opposite – reliability engineering expertise needs to be captured at every step and the algorithm is an enhancement that will be used by the reliability engineer to uncover more maintenance opportunities.

The data scientists will need to understand the accuracy of the sensor, the behavior before sensor failure, the behavior before machine failure and the type of sensor. Everything they do will be based on information learned in this process. For example, in the case of a vibrational failure, Fourier transforms likely will be applied to recover the right signals, whereas a simple degradation failure can be noticed via moving averages.

Find a New Way of Working

Finally, you can expect predictive maintenance to change the way the maintenance organization works. The morning report printout will be replaced and preventive maintenance schedules will give way to predictive maintenance predictions. A larger part of inspections will be conducted remotely and legacy maintenance systems will be complemented by new, more modern tools.

The reliability engineer needs to take on an active role and fit tools that are built around predictive maintenance to new, more effective ways of working that are grounded in reality. The best way to do this is for neither party to invent solutions – they need to work together and evolve a solution that is both feasible from a technical perspective and valuable from an engineering perspective.

Conclusion

Predictive maintenance works best when reliability engineers are in the driver’s seat of the transformation. Their expertise is irreplaceable and needs to be leveraged in guiding data collection, use cases identification, predictive model creation and user experience development. Only then will predictive maintenance achieve its full potential.

References

- McKinsey Global Institute. “The Internet of Things: Mapping the Value Beyond the Hype.” Predictive Maintenance, pp. 70. McKinsey & Company, June 2015. http://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/the-internet-of-things-the-value-of-digitizing-the-physical-world

Figure 1: A Journey Toward Wireless Asset Condition Monitoring

Figure 1: A Journey Toward Wireless Asset Condition Monitoring