There are two kind of Predictive Maintenance "predictions":

Type 1) The bearing will fail in the next two years - way too vague to be practically useful

Type 2) The bearing will fail soon - vague, but possibly useful depending upon shutdown schedules, production requirements, asset criticality, asset health and other factors.

The P to F Curve by Nowlan and Heap

Original P to F Curve

Reliability-centered Maintenance [Nowlan and Heap]

Original P to F Curve

Reliability-centered Maintenance [Nowlan and Heap]

The D-I-P-F Curve [Design-Installation-Potential Failure - Failure] Curve

D-I-P-F Curve by Reliabilityweb.comReliabilityweb.com

D-I-P-F Curve by Reliabilityweb.comReliabilityweb.com

When Stan Nowlan and Howard Heap (with significant help from Tom Matteson) published Reliability-centered Maintenance in 1978 one of the breakthroughs was the P-F Curve which we have since expanded to the D-I-P-F Curve pictured above.

The idea is to inspect an item to detect a potential failure - a potential failure is an identifiable physical condition which indicates that a functional failure is imminent” so that one can schedule a corrective intervention prior to a function failure event.

Like a doctor testing for a virus (testing NOT predicting) so they can issue a diagnosis, highly-skilled technicians use advanced sensing instruments to detect an identifiable physical condition which indicates that a functional failure is imminent. They provide diagnosis not prediction. An airplane full of people would not take off based on a prediction of maintenance requirements.

In the virus test example above, once you have the virus, elimination and "prevention" is no longer an option. Diagnostics and treatments are the best path.

Based on generic statistics, the Doctor could simply predict the likelihood of any individual contracting the virus. They could refine their predictions based on individual behaviors and actual data. That is the business of prediction - great for large populations, terrible for individuals.

SDIPF Curve and Hierarchy of Control

SDIPF Curve and Hierarchy of Control

In order to Predict on an individual basis, one must have already developed the defect.

In terms of Maintenance - the business of repair, renewal, renewal, replacement and inspection, this type of defect in an asset seems normal. Without defects there are not many pure wear outs, so corrective maintenance work would drop significantly. Ouch there goes my overtime or there goes my job! Is that crazy guy talking about trying to eliminate as much maintenance as possible? Yes I am.

That is the danger with blurring the distinction in language between Maintenance and Reliability the way so many vendors and practitioner do these days. “The maintenance concept has become so mistakenly entwined with reliability that the two terms are often used as synonyms. No CEO wants more maintenance – think “high maintenance.” All CEOs want failure-free operations – think “high reliability. Which would you rather be?”

High Maintenance or High Reliability?

Terrence O'Hanlon and Jeff Smith

High Maintenance or High Reliability?

Terrence O'Hanlon and Jeff Smith

To the Reliability Leader, the defect is an invader. Not normal. Not welcome. The defect is something to be eliminated. The Reliability Leader understands that is not simply a small defect that will lead to a failure. The Reliability Leader understands that defects gang up over time. They begin to blind busy maintainers, busy operators, busy engineers and they embed themselves deeply in the assets and in the culture. The Reliability Leader knows there is a mathematical equation that as defects add up, work orders add up, and the end result is a significant process safety incident or possibly a catastrophic process safety incident.

Defect Elimination as a TrimTab

Defect Elimination as a TrimTab

If you conducted a study on your corrective work orders that resulted from "Predictive Maintenance" finds, you may discover that most if not all of them could have been ELIMINATED through precision installation, fastening and torquing. Through precision alignment and balancing. Through precision lubrication (clean, dry, compatible lubrication lifecycle management). Through improved specification writing. Through improved sourcing, etc... You are predicting the near death of your assets from diseases that were caused your own organization's practices and process in many cases. With poor precision practices, you do not need a crystal ball to predict the early death of your assets.

My work stands for ZERO deaths.

Transient or abnormal operation (shutdown, startup and emergency repair) is where 50% of accidents occur. Reduce abnormal operations and you will reduce accidents.

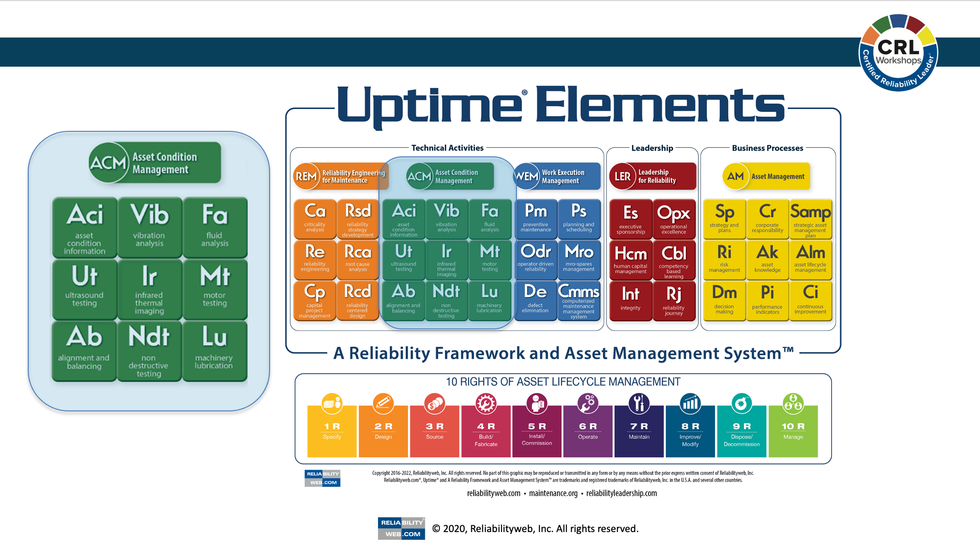

So while change is slow and many love their predictive maintenance programs, our work around Asset Condition Management has reached 30,000 new Reliability Leaders around the world and we are already seeing the effects and outcome in many progressive organizations who are not afraid or breaking away from the pack.

I would like to know what you think about the Asset Condition Management approach or how your journey is progressing with Uptime Elements Reliability Framework and Asset Management System. Please find me at LinkedIn and let me know.

Terrence O'Hanlon

Enquiry: Are you limiting your Return on Investment by taking a Predictive Maintenance approach rather than using an Asset Condition Management approach?

- Objective is to go beyond prediction of failure to ensuring maximum value delivery from asset

- From a Reliability perspective, Maintenance of any type is by nature reactive

- The objective of is management of value delivery NOT prediction of maintenance requirement

- Manages the alignment of activities to ensure asset condition to organizational objectives

- ACM Includes the original intent of Nolan and Heap RCM “Inspect an item to detect a potential failure - a potential failure is an identifiable physical condition which indicates that a functional failure is imminent”

- Asset Condition Management is part of a holistic Reliability Framework and Asset Management System

- ACM stresses precision approaches to block the defect that creates the potential failure (Point P) that leads to the Functional Failure (Point F)

Warning: Asset Condition Management requires that you think for yourself and stand on your own two feet.

Asset Condition Management Domain from Uptime Elements Reliability Frameworkreliabilityweb.com

Asset Condition Management Domain from Uptime Elements Reliability Frameworkreliabilityweb.com

From Your Site Articles

Related Articles Around the Web

Original P to F Curve

Reliability-centered Maintenance [Nowlan and Heap]

Original P to F Curve

Reliability-centered Maintenance [Nowlan and Heap]

D-I-P-F Curve by Reliabilityweb.comReliabilityweb.com

D-I-P-F Curve by Reliabilityweb.comReliabilityweb.com  SDIPF Curve and Hierarchy of Control

SDIPF Curve and Hierarchy of Control High Maintenance or High Reliability?

Terrence O'Hanlon and Jeff Smith

High Maintenance or High Reliability?

Terrence O'Hanlon and Jeff Smith

Defect Elimination as a TrimTab

Defect Elimination as a TrimTab Asset Condition Management Domain from Uptime Elements Reliability Framework

Asset Condition Management Domain from Uptime Elements Reliability Framework