Sun setting on the west side of one of LOOP’s Marine Terminals (Photo courtesy of: Jason L. McMichael of LOOP LLC)

In 2018, LOOP LLC received the Uptime Award for Best Asset Condition Management Program. It highlights a journey that began five years ago and led to many achievements along the way. Here’s how the company re-invented industrial energy usage, applied science and technology to implement an effective asset conservation and improvement program.

The Start of the Journey

The Louisiana Offshore Oil Port (LOOP LLC) is the nation’s largest privately owned crude oil terminal. Initially constructed in 1981 to import crude oil from around the globe, LOOP has grown to become a fully diversified crude oil trading and exchange hub. LOOP is the only facility of its kind in the world where shippers can off-load crude oil from very large crude carriers (VLCCs), load VLCCs, and purchase, sell, exchange, store, blend, or deliver crude oil.

Figure 1: A VLCC moored and connected to LOOP LLC’s marine terminal in the Gulf of Mexico

In February 2018, LOOP’s deepwater oil port became the first U.S. facility capable of fully loading a VLCC for crude export. Today, LOOP handles far more domestically produced crude oil than international varieties. In addition to its pumping and storage facilities, LOOP provides shore services for deepwater Gulf of Mexico production and operates pipelines. LOOP LLC’s onshore facilities can store over 70 million barrels of crude in belowground caverns and aboveground storage tanks. Its unique pumping systems can transport crude at rates in excess of 100,000 barrels per hour on multiple, interconnected pipelines. After several decades of planning and successful execution, LOOP has now established the Clovelly Hub as a strategic component in the global crude oil marketplace.

LOOP is constantly seeking ways to remain market driven and operationally excellent. It enhances its strategies and tactical objectives annually for continued success in the ever-changing petroleum market. The safety of personnel, its environmental stewardship, the uptime or availability of assets, and energy consumption reduction all remain critical components of LOOP’s business performance. Related key performance indicators (KPIs) and metrics, therefore, align with the company’s vision for success. It embeds proactive systems and programs into its culture. The company continues to plan its work and work its plans, taking note of lessons learned and corrective actions along the way and sharing them throughout all facilities. LOOP has made a habit of seeking opportunities for continuous improvement in all aspects of its business, with the help of its owners and strategic partners.

The Workings of the Asset Condition Management Program

Asset condition management is a key component of LOOP’s success. For starters, the company strives to provide a reliable and safe facility where its employees, contractors and customers want to be. Its operator care and predictive and preventive maintenance programs are robust, thus field operators, reliability technicians and maintenance technicians are empowered as the first line of defense against asset failure. The Oil Movement Controllers (OMCs) in the control room are also asset stewards, responsible for alarm management. Additionally, engineers are designing reliability into the systems and eradicating failure out of the assets.

Figure 2: LOOP LLC’s Clovelly Maintenance Crew, from left to right: Trent Rupert, Kerwin Matherne, Ryan Ford, Nat Pitre, Chase Orgeron, Terral Pitre, Anthony Pitre, Cody Pitre, Ricky Lee and Janson Thibodaux

LOOP continues to utilize technology: vibration monitoring, ultrasound, thermography, oil analysis and other traditional asset condition monitoring components of a robust reliability-centered maintenance program. As technology changes, the company embraces condition monitoring advancement opportunities and remains prepared for major shifts in strategy. For example, LOOP is currently enhancing its platform for improved asset condition management by investing in a new enterprise asset management/enterprise resource planning (EAM/ERP) pre-integrated software solution to replace its computerized maintenance management system (CMMS) and financial systems with one application. This system will provide one truth in asset condition and work management status throughout the organization, including associated cost tracking, and will be the foundation for technological advances in true online condition monitoring well into the future. This investment into LOOP’s future is named Project Constellation, as it ties into the overarching technology strategy, which was developed after naming technology as one of the company’s five strategic focus areas in 2017.

LOOP continues to use KPIs to successfully manage what is important and must be measured. As always, data quality is important when it comes to metrics and KPIs, and so is relevance. The company continues to measure the things that should be managed, and where a cultural evolution has already taken place, eliminates data tracking that is no longer pertinent. This leaning out of its metrics and KPIs allows the organization more time to focus on current, relevant tactical objectives that are being embedded into its positive, proactive processes. This has been a recipe for success at LOOP for nearly 40 years.

The Journey’s Results

The results have been rewarding. LOOP achieved a record 99.75 percent uptime on its main oil line (MOL) assets in 2013, remains over 99 percent and has now exceeded 98 percent uptime for nearly a decade.

In 2013, LOOP established a five year goal to reduce its 2012 baseline energy consumption per barrel of crude oil transported by 15 percent. This goal was accomplished with three years to spare and has continued to decrease energy consumption to a current savings of over 30 percent compared to the company’s baseline. Though the organization has significantly reduced its energy consumption, it continuously strives to become even leaner as it realizes this is good for both business and the environment. LOOP appreciates Terrence O’Hanlon’s theory of the triple bottom line, and supports and encourages related initiatives throughout its facilities.

In 2018, LOOP handled over 940 million barrels of crude (over 37 billion gallons in total) at its Clovelly Hub in Galliano, LA, approximately 470 million barrels “in” and over 470 million barrels “out.” The company’s stewardship of these volumes includes adherence to strict standards for environmental releases. LOOP reports every drop of hazardous fluid that leaves containment and enters the water. Accordingly, it reported five environmental releases in 2018. However, the total volume released was only 0.02 ounces, or less than half a teaspoon. That ratio of throughput to release volume was a new record for LOOP and surpassed its prior year. However, its target is always goal zero for both safety and environmental incidents, so there is still room for improvement.

Figure 3: Kerwin Matherne of LOOP LLC and Avery Duet of Danos embody teamwork and collaboration, one of LOOP’s cultural pillars

The company’s efforts have led to numerous recognitions over the years. LOOP has received three Uptime Awards in five years. The company won the Uptime Award for

Best Work Execution Management Program in 2014, the 2016 Uptime Award for Best Green Reliability Program and the 2018 Uptime Award for Best Asset Condition Management Program.

After each Uptime Award, LOOP renewed its commitment to continuous improvement, vowing to not camp out at success or rest on its laurels. In recent years, the recommendations set forth in the American Petroleum Institute’s (API’s) RP1173 for a structured and integrated Pipeline Safety Management System (SMS) were implemented. This includes a Deming model style Plan-Do-Check-Act (or Adjust) component for all of its processes and programs, starting with risk assessments and mitigation evaluations at all operating facilities. There is synergy between RP1173 and ISO55000, so LOOP’s efforts are yielding a win-win for the company and its assets through a risk-based approach to asset management and safety.

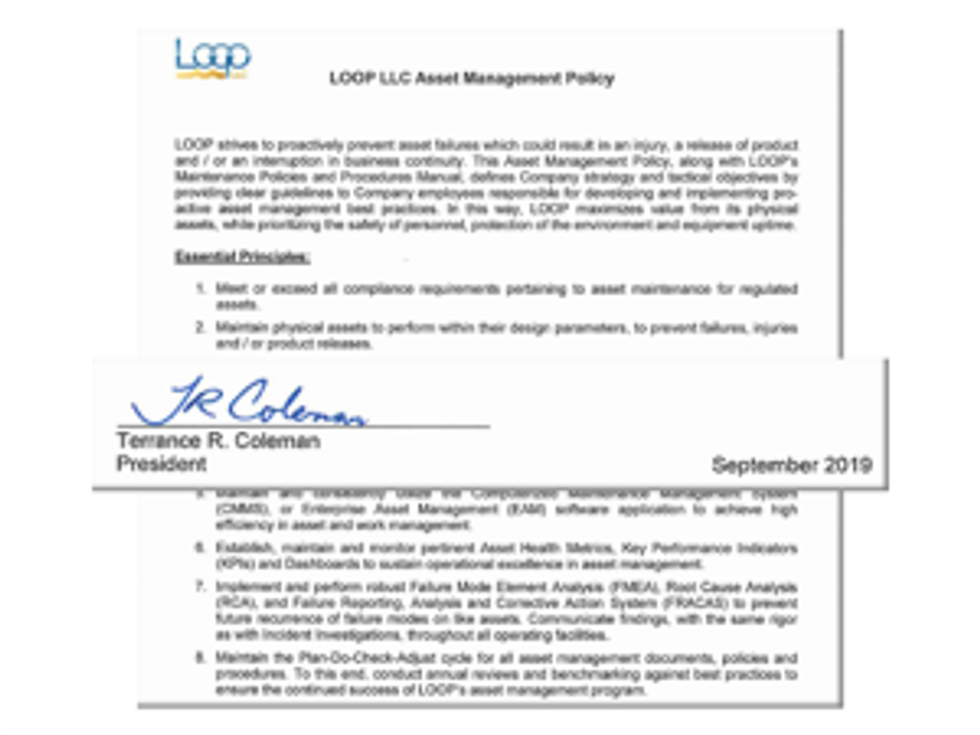

The Uptime Award selection as the

Best Asset Condition Management Program was based, in part, on LOOP’s continued uptime performance, risk-based asset management program and its asset management policy. This policy is signed by LOOP’s President and is embedded as a foreword to the organization’s Maintenance Policies & Procedures Manual, just as its safety policy is for its Safety Manual. These policies establish executive support and set the tone for asset, work and safety management. Through threat assessments and risk management, the company is taking luck out of the equation for uptime and, more importantly, for safety and environmental incident prevention.

Figure 4: The essential principles of LOOP's asset management policy

Figure 5: LOOP LLC receives its third Uptime Award in five years at the International Maintenance Conference in Bonita Springs, Florida, December 12, 2018. Pictured left to right for LOOP: Naresh Copeland, Brian Pertuit, Kerwin Matherne, Terry Coleman and Darren Faucheux

Figure 6: Some members of the LOOP LLC leadership team after an August 2019 Safety & Environmental Roundtable

Figure 6: Some members of the LOOP LLC leadership team after an August 2019 Safety & Environmental Roundtable

LOOP LLC is a joint venture of Marathon Pipeline LLC, Shell Oil Company, and Valero Terminaling and Distribution Company. These owner representatives extended their support and shared best practices that have proactively improved LOOP’s performance in safety, environmental stewardship and reliability. All LOOP employees, its owners and strategic partners take pride in the organization’s continued stellar team performance and successes.

With an embedded, proactive culture, a clear focus on “getting it right” and a passion for continuous improvement, LOOP continues its journey toward operational excellence.

Special Recognition

Special Recognition

To coincide with LOOP’s 3 Uptime Awards to date, the author has requested that Uptime magazine recognize the following three reliability champions on behalf of the LOOP team.

Figure 6: Some members of the LOOP LLC leadership team after an August 2019 Safety & Environmental Roundtable

Figure 6: Some members of the LOOP LLC leadership team after an August 2019 Safety & Environmental Roundtable Special Recognition

Special Recognition Morgan B. Wolfe, CMRP, is the Sr. Vice President of Operations at LOOP LLC, where he also once served as the General Manager and has supported all of the asset condition management initiatives referenced in this article. Mr. Wolfe developed the Reliability Department at LOOP and his vision provided the genesis for many of LOOP’s reliability initiatives. Mr. Wolfe is an executive owner in LOOP’s Pipeline SMS program. He has over 40 years of experience in the oil and gas industry, and obtained a Bachelor of Science degree in Mechanical Engineering from Louisiana State University in 1979.

Morgan B. Wolfe, CMRP, is the Sr. Vice President of Operations at LOOP LLC, where he also once served as the General Manager and has supported all of the asset condition management initiatives referenced in this article. Mr. Wolfe developed the Reliability Department at LOOP and his vision provided the genesis for many of LOOP’s reliability initiatives. Mr. Wolfe is an executive owner in LOOP’s Pipeline SMS program. He has over 40 years of experience in the oil and gas industry, and obtained a Bachelor of Science degree in Mechanical Engineering from Louisiana State University in 1979.