Oil analysis is essential for maintaining equipment reliability and life span. In this process, data analysts assess whether samples indicate abnormal working surface wear and tear likely to impede performance or shorten specific equipment life span. The problem is, traditional analysis occurs after the fact. By then, signs of wear and tear when finally detected threaten optimal operation and increase the possibility of downtime.

But, what if the algorithms that create predictive analytics could be harnessed to detect potential abnormalities in engines, turbines, hydraulics and other equipment from a seemingly normal oil sample before they occur? In fact, such algorithms have been put to use successfully and are growing in acceptance in the form of an artificial intelligence (AI) platform. Combined with the expertise of data analysts and the concept of machine learning, AI has become vital for maintaining equipment and ensuring its useful life.

The Oil Analysis Process

Oil analysis, also referred to as oil condition monitoring (OCM), begins with a small sample provided by a company to a laboratory for analysis of wear, fluid condition and contamination. If any of these conditions are present in the sample, a human analyst recommends corrective action. Analysis per sample can take up to five minutes, which may not sound like much time, but feels like an eternity when you consider the quantity of samples submitted on a daily basis. One U.S. firm reports 1.2 million samples for oil analysis in 2018.

Traditional analysis is limited in scope and scale, which creates a major problem. There are only so many data points an analyst has time to consider. A typical figure is 100, which may be inadequate considering the seemingly endless number of data points and, equally important, the interrelationship of those points in determining one of four sample severity classifications: normal, monitor, abnormal and critical. Some abnormalities, such as the unwanted presence of iron and lead, in a sample are obvious for showing wear, but others may not be readily apparent.

After analysis, the majority of samples are categorized as normal, but that does not change the time that must be committed to each one. Even normal findings can be time consuming, which is why some in the OCM industry have turned to two high-tech resources for quicker, accurate and more efficient data analysis: artificial intelligence and machine learning.

The Transformation of the Oil Analysis Process

To understand how all this applies to equipment maintenance, start with what’s commonly called big data. Accessing potentially vital information buried in the reams of big data is as vital to maintenance as it is to economics and investments. For equipment, such as engines, gears and hydraulics, AI has become the platform to enable identification of troubling trends in a sample. It accesses thousands of data points, many of which are inaccessible through traditional analysis, and produces a report for the analyst to review.

Machine learning is a subset of AI. Here, the focus is on patterns and relationships between data. The machine learns from historical material fed by the data analyst. Information of this type is developed into a model that enables the computer to learn. The model, unlike traditional analysis of oil samples, is not rules-based, allowing for different interpretations to be easily factored in.

There is a direct relationship between the quality of traditional oil analysis and the machine learning model. Quality demonstrated by the experience of the analyst in many ways is as fundamental to machine learning as it is to the AI platform. Both learn from experience in much the same way as an apprentice learns a craft from a longtime practitioner.

The reality is that the machine continues to learn after AI does the data points’ heavy lifting prior to the analyst’s review. The impact of this process on maintenance is clear. Unlike traditional analysis and its after-the-fact detection of abnormal trends, an AI platform-driven oil analysis identifies precursors of wear on equipment or changes in fluid conditions. A department can take action before there is either downtime or a reduction in the equipment’s useful life. One example already in use by an international certification agency is a platform containing an aggregate consisting of millions of samples and results from more than a decade of analysis.

“It’s a hugely rich data set we were able to mine,” says Jonathan Rudnicki, the OCM project leader for the international certification agency. “We were able to look for correlations between different results to assist in identifying different permutations that best predicted the condition of the sample and whether any actions were required.”

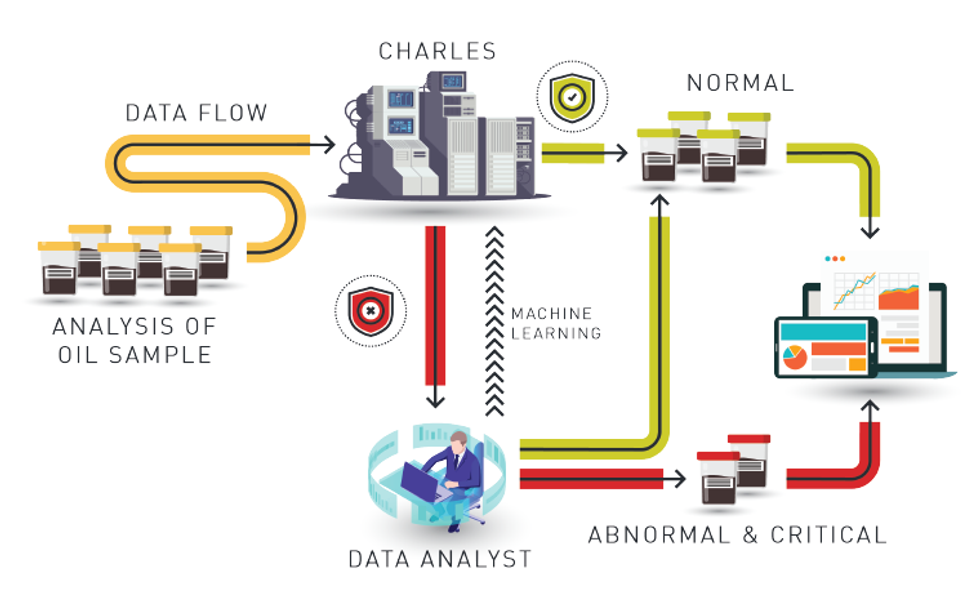

Figure 1: Machine learning identifies patterns and correlations in historical data

Historical data in this AI/machine learning environment is divided into two parts: one for training and the other for testing the model. During the latter, areas with potential data quality issues are identified and resolved. The model deep dives into data relationships as it explores features and/or feature combinations from the millions of samples. Details from each sample are recorded into a laboratory information management system and sent to the AI platform for interpretation on the level of severity. If the sample is found to be abnormal or critical, the system, along with the analyst, assesses possible corrective actions, followed by a quality control check to assure the accuracy of the findings before returning the sample to the company that submitted it.

The Experience of a User

Jami Melani, heavy duty/technical services field manager for a longtime provider of motor oils and specialty lubricants, experienced firsthand the importance of accurate and timely oil analysis. He says AI/machine learning platforms are inevitable because of rapidly evolving changes within the industries his company serves.

“Equipment and lubricants are advancing at a faster rate and you have to automate to keep pace,” Melani said. “(Traditional) platforms don’t take into account severity of the duty cycle.” Some examples he provided include haul trucks and loaders with unique load and wear ratings. Their differences may slip through traditional analysis, but are adjusted within automated programs.

“Every time someone puts another sample in, the system will weed out anomalies and learn on itself,” he said.

AI and the Future of Lubricant Maintenance

AI and machine learning are not threats to the continuing need for OCM analysts. Since the platform can determine normal samples instantaneously, analysts can better spend their time on more detailed analysis of exceptional samples. However, there will still be a few normal ones they review as part of the ongoing quality check.

Additionally, findings and relationships subject to data analysis are integral to continued machine learning and the growth of predictive analytics for maintenance. Both are proving to be indispensable for maintaining engines or other equipment by reducing unplanned downtime and the possibility of machine failure while increasing return on investment.

As Melani aptly summarizes, “It’s data and what you can do with it.”