The SDIPF Reliability Curve begins with the birth of the P to F Interval in 1979.

“Determining the interval for on-condition inspection of an item subject to metal fatigue. Once the rate of decline in failure resistance has been determined, an inspection interval “AT” is established that provides ample opportunity to detect a potential [P] failure before a functional [F] failure can occur.” Excerpt From: F.S. Nowlan. “RELIABILITY-CENTERED MAINTENANCE.” 1979

Forty-two years later many of the benefits from Stanley Nowlan and Howard Heap’s Reliability-centered Maintenance are still setting the standard for achieving asset reliability.

Selecting the best condition monitoring technologies, approaches and periodicities based on failure mechanisms and failure modes is a basic building block of high reliability organizations. As solid as the original P to F curve is, it is only one part of a holistic approach to optimizing value from assets at all asset lifecycle phases.

Even as we typically work in silos, it is critical to understand the dynamic connections between Reliability Strategy Development and Asset Criticality and Risk Management and Decision Making and Asset Condition Management and Preventive Maintenance and Work Execution Management and Asset Knowledge and Asset Management across Asset Lifecycles and based in policy, strategy and plan to align energy toward creating value from assets in achievement of organizational objectives. That alignment and energy must be intentional.

Asset Management creates the intentional management system to assure opportunity and risk are managed or “treated” at the level appropriate to achieve organizational objectives as set by top management.

The Time Machine

One of the challenges with Reliability is that it is disconnected in time and usually pays its significant dividends slowly over long periods of time. With management typically focused on short term projects and goals, it is easy for organizations to depreciate reliability and realize loss of consistent value generation from assets in a much more rapid fashion that it took to gain it.

The fallacy of "improving" reliability through maintenance has been chased for the past 40 years and like Sisyphus pushing his rock up the hill, a few dedicated teams of driven people make it to the top, but the rock inevitably rolls back down again within 2-3 years. The "best practice" maintenance send us to the "planned" domain where we develop systems to anticipate and deal with failures through efficient maintenance. The only problem is maintenance cannot influence all the causes of breakdowns. The "planned" domain is unstable and quickly becomes a "reactive-planned" domain with an almost unescapable gravitational pull.

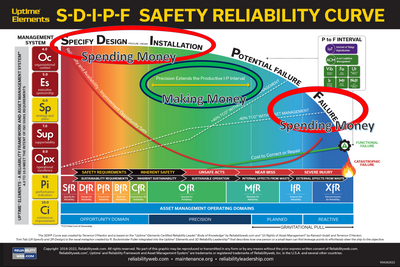

The SDIPF Curve is a visualization that attempts to graphically "bend time" to the benefit of investing in and applying reliability efforts by showing a lifetime snapshot of the asset over time.

I offer no apologies to Stan Nowlan nor Howard Heap for absconding with their excellent work that was intended as a condition monitoring periodicity determinant as it is so finely fit for my own asset lifecycle purposes. Thank you, gentlemen, it with high respect I use your work. Others have have treated your P to F curve much worse than this.

Some of the ideas expressed in the SDIPF Curve:

- It visually expresses the full asset lifecycle phases

- It visually expresses reliability and availability "leverage" or "influence level" or "opportunity sets" over the asset lifecycle phases

- It visually expresses total cost of ownership with and without formal asset management [estimated at a typical 40% advantage]

- It visually expresses the way to improve reliability and maintainability is to improve the asset itself early in the asset lifecycle

- It expresses respect for the original intent of the P-F Curve as a method to determine asset condition monitoring periodicity

- It visually expresses operating maturity domains and encourages moving to the precision and expansive domains

- It visually expresses the gravitational pull (p to f repeating cycle) of the “reactive-planned” domain where systems have been put in place to anticipate and plan for asset failures, however significant unplanned failures continue to surprise the team and consume resources.

- It shows the limited reliability and availability "improvement" opportunities available in the operation and maintenance phases.

What ideas do you see?

Here is some of the more technical aspects of the Asset Lifecycle theory embedded in the SDIPF Curve:

Availability is defined as the probability that the system is operating properly when it is requested for use.

Reliability is the probability that a system or asset will operate in a satisfactory manner for a specified manner for a specified period of time when used under stated conditions.

Reliability and Availability can specified, predicted and measured. The biggest opportunities to "improve" them exist during the early asset lifecycle phases of specification, design, procurement, build/create, install/commission. Once in operation, the opportunity sets to improve the inherent reliability is limited.

Maintainability is defined to be the probability that a failed system will be restored or repaired to a specified condition within a period of time when maintenance is performed in accordance with prescribed procedures.

Maintainability can be specified, predicted and measured. The biggest opportunities to "improve" it is through planning and execution.

Maintenance includes all scheduled and unscheduled actions necessary for retaining an item in, or restoring it to an operational condition. Maintenance includes repair, replace, remove, restore, renew, testing, modification, inspection, servicing calibration, overhaul, condition verification and so on. Maintenance may or may not result in downtime. Maintenance is usually a major contributor to life cycle cost.

Here are some of the Cultural aspects embedded in the SDIPF Curve:

The Target we are attempting to express is the expansive opportunity domain by through the precision domain by creating an engaged, empowered, cross-functional reliability leadership culture.

Traditionally the maintenance team owns breakdowns or unreliability. They are the specialists who have the know how to react quickly to get the assets back online. They repair, they replace, they renew, they restore, and they inspect.

Unfortunately, many organizations also default responsibility for reliability to the maintenance teams without providing all the controlling influences, setting up a cycle of unplanned breakdowns that often lead to a safety, environmental or economic catastrophe.

Engineering, Procurement, Operations, Quality, HR/HCM, Training, Safety, Stores, Capital Projects, IT, Sales, Marketing, Top Management are all stakeholders in reliability and make decisions that enable and disable reliability. A coordination effort, guided by policy, strategy and plan is required to assure intentional value.

Getting these stakeholders engaged is what Uptime Elements Reliability Framework and Asset Management System is all about. I hope the SDIPF Curve helps you tell the story that you need to tell to engage the stakeholders who can enable your reliability journey! Please let me know how I can support that.

The SDIPF Curve is created as part of Uptime Elements Reliability Framework and Asset Management System by Terrence O’Hanlon. It is inspired by 10 Rights of Asset Management by Ramesh Gulati and Terrence O’Hanlon.

Ramesh has his own fantastic ideas on Asset Lifecycle Management and this work does not attempt to speak on his behalf. He is very capable for speaking for himself and I do not wish to put words into his mouth. This work represents Terrence O'Hanlon.

I would enjoy hearing from you about our ideas around the SDIPF Reliability Curve. Catch me at LinkedIn.

More References:

Understanding the Difference Between Reliability and Availability

Relationship Between Availability and Reliability

RAP Talk: 10 Rights Of Asset Management by Ramesh Gulati, Co-Author [Video on demand]

US Navy Analysis of Submarine Maintenance Data Part 1

US Navy Analysis of Submarine Maintenance Data Part 2

US Navy Analysis of Submarine Maintenance Data Part 3

- Reliabilityweb Completing the Curve ›

- Reliabilityweb Predictive Maintenance is a near Death Experience ›

- Reliabilityweb Transit Map ›

- Reliabilityweb Right 1 Specify for Reliability [SfR]: The 10 Rights of ... ›

- Reliabilityweb S-D-I-P-F Safety Reliability Curve ›

- From a Different Angle: A Perspective - Defects, P-F and the ... ›

- Maintenance Rebuild Decision: Reuse or Replace - Reliabilityweb ... ›

- Why People Do Not Understand the P-F Curve - Reliabilityweb: A ... ›

- Reliabilityweb Why Asset Condition Management [ACM]? ›

- Reliabilityweb Innovation in Video-Based Asset Condition Management ›

- Reliabilityweb Steal These Graphics ›

- Reliabilityweb The SDIPF Curve is a visualization lifetime of the asset ›

- Reliabilityweb Steal These Graphics Downloads ›

- Reliabilityweb What Does It Feel Like to be on the Reliability Journey? ›