The last thing people want to do is change. What a pain in the neck!

The great news is that using the approaches of Asset Condition Management from Uptime Elements Reliability Framework and Asset Management System to upgrade your predictive maintenance approach is simply a suggestion. It is a new perspective for you to discover opportunity to advance reliability and asset management in.

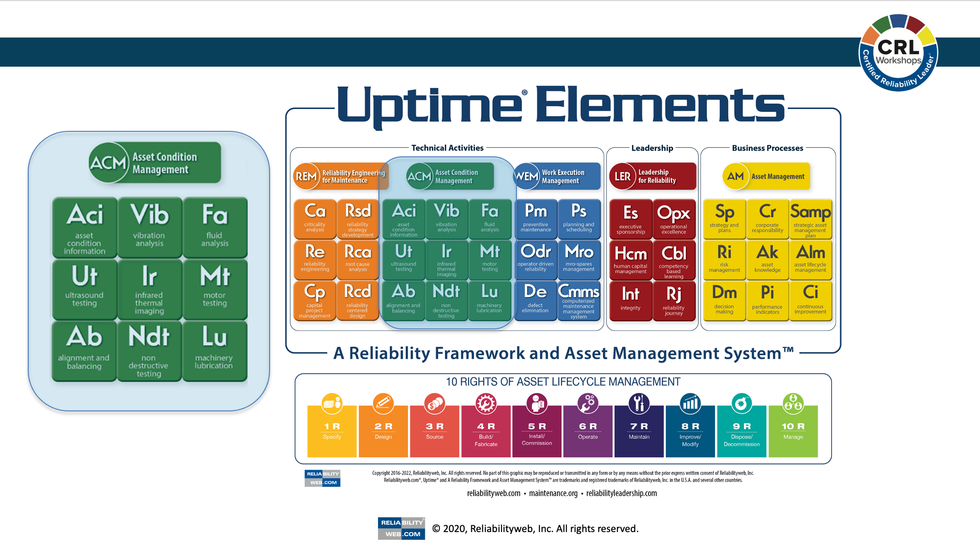

Asset Condition Management Domain Uptime Elements Reliability Framework

Asset Condition Management Domain Uptime Elements Reliability Framework

Asset Condition Management Domain from Uptime Elements Reliability Framework

Why change from Predictive Maintenance to Asset Condition Management? In one word - value. The focus on a Predictive Maintenance program is when to perform maintenance on an asset or system. The focus on an Asset Condition Management program is to maximize value from assets in alignment to organizational objectives.

What is NOT changing with Asset Condition Management is early and effective detection of a physical conditions that indicate that failure is imminent.

Maintenance is and always will be a cost. Maintenance will always be reactive from a Reliability point of view. Preventive, predictive, reactive, corrective, emergency. Regardless of the type, all costs associated with it will end up on the cost side of the ledger. CEOs are rarely interested in costs unless you are cutting them.

CEOs do not like cost and they generally love value generation.

Most organization purchase equipment dreaming of smooth operation over the full lifecycle and willing to accept a certain amount of wear and tear for rigorous use.

Uptime Elements Source of Defects

Reliabilityweb.com

Uptime Elements Source of Defects

Reliabilityweb.com

The risk of NOT changing is the harsh reality that many of the activities around "Predictive" Maintenance are defensive strategies that detect failures created by poor specification, poor maintainability, poor reliability, poor design, poor installation, poor commissioning, poor acceptance testing, poor operation, poor purchasing, poor raw material quality, poor process input, poor material storage and handling, poor maintenance workmanship.

[D-I-P-F as Hierarchy of Controls by Terrence O'Hanlon August 2020]

D-I-P-F as Hierarchy of ControlsTerrence O'Hanlon

D-I-P-F as Hierarchy of ControlsTerrence O'Hanlon

Are we wearing out our assets or breaking them?

Modern Reliability theory states that only a small amount of your equipment fails due to age or wear out. Most of your equipment breaks well before it can fail due to age or wear out.

Your "predictive" maintenance program is predicting failures that your own practices are causing and the organization has settled into a smooth pattern of accepting predictive maintenance as the price one pays for these operating sins such as failure to align new installations or failure to lubricate properly from day 1.

Your organization may be missing the significant value generation operation that come with Asset Condition Management and use of Uptime Elements Reliability Framework and Asset Management System and 10 Rights of Asset Lifecycle management to operate from the Precision Domain or Expansive Domain and eliminate the bugs from every phase of the asset lifecycle.

Uptime Elements Reliability Framework and Asset Management System

Terrence O'Hanlon, Reliabilityweb.com

Uptime Elements Reliability Framework and Asset Management System

Terrence O'Hanlon, Reliabilityweb.com

Change or Die! Change is Hard!

During a lecture at Harvard University I attended with Maura Abad during a Kegan and Leahy Change Management workshop, the Harvard Medical School heart surgeon presented a shocking set of statistics. When patients who are offered heart valve replacements are presented with a simple list of lifestyle changes that they must make to extend their lives 5 -10 years in order to make the most of their new heart valves, only 1 in 9 make the changes permanently. These are relatively simple changes like increase walking, drinking more water, sitting less, eating less saturated fats, eating more fresh foods, etc...

A study in 2016 showed 65% of organization reported their Predictive Maintenance programs were in need of improvement.

A new breed of IoT system marketer has also discovered the term "Predictive Maintenance" and is now selling it as one of the "Rainbow and Unicorn" Dreams of Digitalizations. Many will drink the sugar water just as they have in the past, but the sugar high will wear off and the client will still have a thirst. That is who we look for. When they are ready for us, we are ready for them. People and organizations who are ready for reality and substance in place of fairy tales. Asset Condition Management is an important element of Visual Asset Management and the Digital Twin Frameworks that we are or will manage our assets with in the very near future.

Uptime Elements Digitalization Strategy Framework

reliabilityweb.com

Uptime Elements Digitalization Strategy Framework

reliabilityweb.com

If only 1 in 9 choose to make changes to extend life - I am aware that we have our work cut out for us to change from 40 years of "predictive" maintenance to Asset Condition Management [ACM] but I am all in.

I stand for Zero Deaths, Zero Waste and Zero Downtime!

I invite you to join me to advance this work. Reliability is safety.

Please find me at LinkedIn and let me know what you think.Terrence O'Hanlon

Terrence O'Hanlon

From Your Site Articles

Related Articles Around the Web

Asset Condition Management Domain Uptime Elements Reliability Framework

Asset Condition Management Domain Uptime Elements Reliability Framework

Uptime Elements Source of Defects

Reliabilityweb.com

Uptime Elements Source of Defects

Reliabilityweb.com

D-I-P-F as Hierarchy of ControlsTerrence O'Hanlon

D-I-P-F as Hierarchy of ControlsTerrence O'Hanlon

Uptime Elements Reliability Framework and Asset Management System

Terrence O'Hanlon, Reliabilityweb.com

Uptime Elements Reliability Framework and Asset Management System

Terrence O'Hanlon, Reliabilityweb.com

Uptime Elements Digitalization Strategy Framework

reliabilityweb.com

Uptime Elements Digitalization Strategy Framework

reliabilityweb.com