Right Type

As a first step in the lubrication of equipment, refer to the OEM manual. The OEM should be contacted if there are any questions. With old equipment the OEM manual may be outdated and better lubricants may be available. When in doubt, utilize your lubricant supplier along with the OEM.

Two major classes of lubricants are oil and grease. The selection of the type is based on the application. Greases are used extensively in the lubrication of small bearings. As a rule of thumb use oil where possible because it can be cooled and filtered but this is not possible for many applications where grease is the better choice. The following are applications for grease:

•To decrease drippage and splattering, as the grease acts as an additional seal to reduce leakage

•To reach hard to get to lubrication points where lubrication frequency is important and when oil circulation is impractical

•To seal in the lubricant and assist in sealing out contaminants such as water, dirt and damaging corrosives

•To protect metal surfaces from rust & corrosion

•To lubricate machines with intermittent operation

•To suspend solid additives such as moly or graphite

•To lubricate sealed-for-life applications

•When extreme or special operating conditions exist

•When machine parts are badly worn

•When noise reduction is important

Greases are composed mainly of oil dispersed in a thickener with additives. Typical grease is about 85% oil. It is the oil which does the lubricating in grease. The NLGI classifies greases according to consistency with the following grades increasing in hardness: 000, 00, 0, 1, 2, 3, 4, 5, and 6. The most common NLGI grade is #2. At high speeds #3 may be used and at low temperatures and in centralized systems a 0 or 1 is used.

Most large equipment is oil lubricated and selection of the right type is critical to reliability. Two major factors in selection of an oil based lubricant are the correct viscosity and additives in the formulation. For a more complete discussion of viscosity please refer to Basic Principles of Viscosity and Proper Selection Techniques published in Lubrication & Fluid Power (LFP). For a more complete discussion of additive types, please refer to All Lubricants are not Created Equally (Basic Concepts in Formulation of Finished Lubricants) which was published in LFP in 2006.

OEM's will recommend the correct ISO viscosity grade for their equipment based on the operating temperature. Table 1 classifies kinematic oil viscosity in centistokes for industrial lubricants based on the ISO grade which is the midpoint of a viscosity range +/- 10%.

Since grease is primarily oil which does the lubricating; the correct viscosity must be selected in the grease formulation. Table 2 provides guidelines on the selection of the correct viscosity in grease.

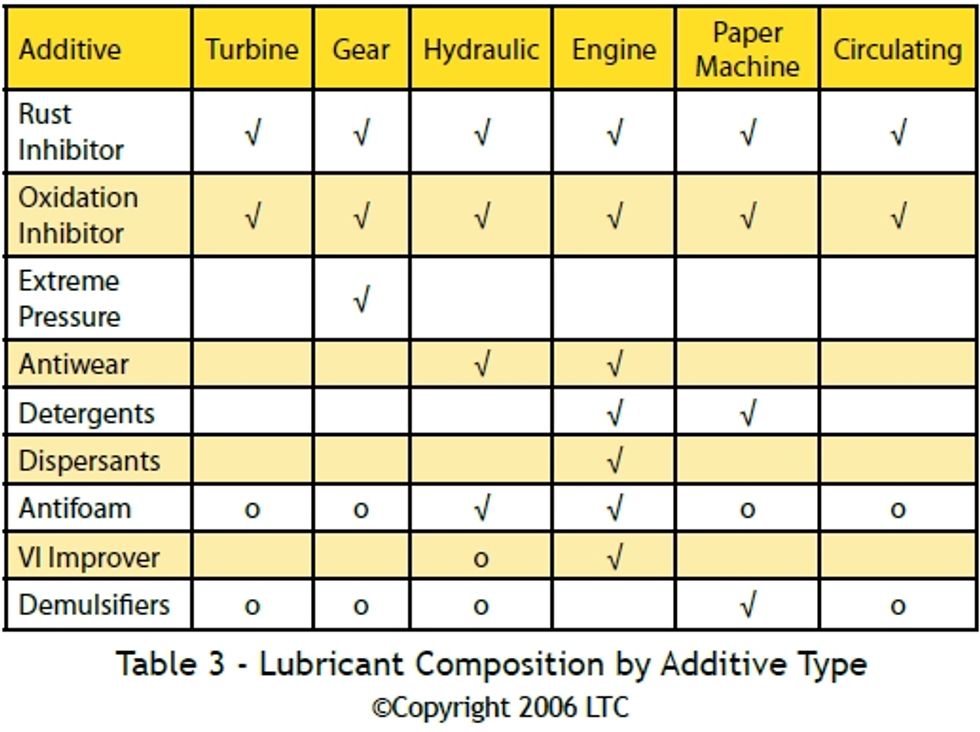

Once the correct viscosity has been determined, the correct lubricant type based on additive composition needs to be selected. Lubricant formulations consist of a base stock and additives. Most base stocks are mineral oils from refining of crude oil. Table 3 summarizes lubricant composition in various lubricant types.

Lubricants in Table 3 with 'o' signify the additive is not in all formulations but is optional for specific applications.

Right Quality

Once the right type of lubricant has been selected, it is important to select a high quality lubricant. Quality is both the ability of the lubricant to meet OEM specifications based on performance on ASTM tests and the cleanliness of the fluid which is delivered. You can have the highest quality lubricant, but if is not handled properly during delivery or storage it will not perform as expected.

Product data sheets provide useful information on lubricants and their behavior on ASTM tests which provides information on their performance on equipment. The best test for a lubricant is how it has performed in your plant, but there are some situations where a lubricant is selected only on specification tests. A series of articles was published in 2005 in LFP on turbine, hydraulic, and gear oil specification tests. Please refer to these articles for an in-depth coverage of lubricant specification tests and how they can help in the selection of the right quality lubricant.

The following summary is best practices to apply in maximizing lubricant quality:

•Utilize specification tests on product data sheets to compare lubricants

•Contact OEM's for minimum specification requirements

•Set minimum lubricant specifications with suppliers

•Set standards on new lubricant deliveries but be reasonable. During the delivery process it is difficult to maintain high levels of cleanliness. Most hydraulic oils need to filtered before use

•Utilize certificates of analysis for water content and viscosity on delivered lubricants

•Routinely run more extensive tests with an oil analysis laboratory to determine if supplier is meeting minimum requirements

•Don't utilize price as main criteria in supplier selection

•Establish return criteria in lubricant contracts

Right Amount

Grease Lubrication - More is not better. Too much lubricant in a system can be as destructive as not enough, as evidenced by the over greasing of electric motors, which happens to be a major failure mode. The use of the formula in Figure 1 will assist in greasing rolling element bearings with the correct amount.

This calculation will give you the number of ounces to add to a bearing during greasing. This is especially important when greasing electric motors because of the tendency to over grease. In order to add the correct amount, grease guns need to be calibrated on their delivery of number of shots /ounce. This can be completed by using a postage scale to weigh out one ounce of grease. An easier method is to count the number of shots to fill a 35 mm film canister, which is approximately one ounce of grease. Once the guns have been calibrated, try to use the same grease gun type consistently for the same application. Some of the newer guns will indicate the amount being added.

Oil Lubrication - Centralized oil systems add the right amount at the right time. This discussion will focus on the having the correct level in oil baths and splash lubricated gear boxes.

Many small pumps are lubricated by oil baths as illustrated in Figure 2. The correct level for a bottle oiler bath should be at the middle of the lowest ball.

Large pumps and process steam turbines which have journal bearings are often lubricated with the use of slinger rings as illustrated in Figure 3. The oil level with slinger rings should be set at 1/8 to 3/8 inches from the bottom inside edge of the ring. The faster the speed the lower the level should be.

Splash lubricated gear boxes are very common where both gears and bearings are lubricated. Enough oil needs to be splashed up for cooling and for lubrication. An oil level too high will cause churning, which will over heat the oil, while a level too low will not provide proper oil cooling and lubrication for bearings and gear teeth. Spur helical, bevel and spiral bevel gears are lubricated with the gears dipping into the oil at twice the tooth depth. The OEM will provide information on the correct oil level.

Worm gears consist of a steel worm and a bronze wheel with either the worm being above or below the wheel. Figure 4 illustrates a worm below the wheel, where the oil level is normally set just below the worm center line. With the worm above the wheel, as illustrated in Figure 5, the oil depth ranges from just above the wheel tooth depth to the center line of the wheel. The oil level is dictated by the speed. The higher the speed, the lower the oil level to minimize churning.

Right Place

Once we have selected the right type of lubricant and the quantity to be added, we need to apply it at the proper location. Adding the wrong oil to a lubrication point is not uncommon. It will usually go undetected until a problem occurs or, with an oil analysis program, detection can be at an early stage, avoiding possible equipment damage.

All lubrication points should be properly labeled as to the lubricant to be added. Lubricant manufactures provide lube tags for proper identification of the proper lubricant to be used at the lube point. A typical tag is illustrated in Figure 6.

A good practice is to use separate containers for different lubricant types, as mixing lubricants with different additive packages is not recommended. Normally each lubricant supplier color codes their tags by lubricant types. In Figure 6, all of their hydraulic oils would be red tags, but with different ISO numbers such as ISO 46 and 68. Containers should also be properly tagged, along with the drums or totes where the oil is transferred to the container. This will minimize the possibility of adding the wrong oil. The following is a summary of best practices for the addition of lubricant at the right place:

•Become acquainted with lubrication points on new equipment through the OEM manual

•Train personnel on correctly adding lubricants to equipment

•Label all equipment lube points with color coded lube tags, which contain ISO viscosity, obtainable from lubricant supplier. Type of lubricant based on color

•Lube containers should be used for only one type of lubricant and should have a color coded tag for lubricant type. Ideally use only one container per lube type and ISO viscosity

•Apply label to lube containers

•Apply tags to totes and drums

Right Time

Grease - Once we have established our program with the right type, quality, amount, and place, we need to establish proper lubrication intervals. Grease frequencies can be determined by using charts, but the following easy calculation is also is used:

Oil - The frequency of changing lubricants depends upon the type of system and size of the reservoir. Initial guidance is provided by the OEM and should be adjusted based upon the environmental conditions.

Small reservoirs (<50 gallons) in non-circulated systems are often changed on a certain frequency based on OEM recommendations and experience. As an example, small ANSI centrifugal pumps in plants hold less than two quarts of oil and the oil is changed over a wide range of intervals. I know one plant that will change every quarter while another using the same type of pumps will change every two years. The environmental conditions dictate the change frequency. The plant changing quarterly has to deal with difficult conditions on water ingression and contamination, while the plant changing biannually has much more favorable conditions. This also applies for splash lubricated gear boxes or any bath lubricated system. To determine the correct change frequency for similar equipment under similar conditions, statistically evaluate the condition of the oil through oil analysis tests. This can provide useful information on establishing change frequency.

Change frequency for large systems (>50 gallons) should be established with oil analysis condition monitoring tests. Two major failure mechanisms for lubricants are contamination (particles/water) and oxidation. Routine visual monitoring of the oil is important. Oils that are getting darker indicate possible oxidation and should be further evaluated. Oils appearing hazy or having suspended solids indicate excessive contamination and should also be further evaluated.

Oxidation is one of the primary reasons lubricants fail, and it's temperature dependent. For every 18°F increase in temperature the oxidation rate doubles which cuts the oil life in half. This is noticeable over 140°F. When oils oxidize they produce sludge, varnish, and acids all, of which can cause equipment damage. A very useful test is to monitor the increase in the acid number of a lubricant through oil analysis and to set condemning limits for the oil.

Excessive water contamination can be determined with a Karl Fisher test, and particle counting can measure the cleanliness of oil. Both of these tests can be included in an oil analysis testing program.

The following is a summary of best practices for oil change frequency:

•Utilize OEM recommendations for change frequency

•Set frequencies for small systems based under high operating temperature

conditions

•Cost of changing lubricant is minimal compared to potential equipment damage and downtime; therefore err on the side of changing too frequently

Summary of Lubrication Best Practices

•Assign lubricant program to one person

•Conduct lubrication survey on equipment and keep updated

•Develop lubrication scheduling through CMMS or other electronic program

•Keep records of lubrication activities

•Utilize OEM and lubricant supplier to ensure use of correct lubricant

•Consolidate lubricants without compromising performance

•Utilize competent personnel for lubrication and provide adequate training

•Set equipment cleanliness as goal to proactive maintenance

•Establish an effective oil analysis program for proactive and predictive maintenance

•Practice continuous improvement with lubrication program

Lubricant Supplier Selection

An effective lubrication program is a partnership between the lubricant supplier and the end user. This includes both the lubricant manufacturer and distributor/marketer. Selecting the correct supplier is a very important step in establishing a world class lubrication program and should not be taken lightly. Don't select or change suppliers based strictly on price.

The criteria in Table 4 should always be used in selecting a lubricant supplier. No one single factor such as price should determine the supplier selection.

The following is a summary of each of the selection factors:

Product Quality

•Lubricants are not all created equal

•Set minimum specifications through ASTM tests

•Adhere to OEM guidelines

•Request data from suppliers not reported on product data sheets where needed

•Utilize outside laboratories to evaluate suppliers when appropriate

Price

•Never base selection of a lubricant supplier solely on price

•Utilize high price synthetics where appropriate to extend equipment reliability and drain intervals

•Don't let purchasing make final decision

Logistics

•Most deliveries, especially packaged items, are provided by lubricant distributors

•Proximity and response time are important factors in selection of supplier

•Require cleanliness and dryness in oil deliveries, but don't be unreasonable

•Utilize Just-In-Time where appropriate

Technical Service

•Evaluate potential suppliers based on innovative approaches for lubricant program improvement

•Utilize lubricant suppliers expertise in troubleshooting lubricant related equipment problems

•Consolidate lubricants without compromising performance

•Request that the supplier run compatibility tests before changing suppliers

Conclusion

Establishing a world class lubrication program, through applying the five rights of lubrication, will pay dividends in the long run by enhancing equipment reliability resulting in major bottom line savings. Establishing the right program requires planning and work and the lubricant supplier and OEM should be utilized when needed. The first step is to recognize and promote the importance of a well designed lubrication program to management and then implement the program. Of course, implementation is the most difficult step, but you will find it is well worth the effort.

References

1. Bannister, Kenneth (2nd edition) Lubrication for Industry, Industrial Press, 2007

2. Lansdown, A.R. Lubrication and Lubrication Selection, Mechanical Engineering Publications, 1996

3. Neale, M.J. Lubrication and Reliability Handbook, Butterworth and Heinemann, 2001