Reading Skills and Quoting from Mark Twain

The relatively few retired engineers that are willing to pass down their experience to other generations are unanimous in at least one recommendation: The learning process of an engineer starts with acquiring reading skills. Today, people with what passes for "education" will often have to accept jobs that require little or no education. In contrast, and with far fewer exceptions, people with marketable skills are likely to find gainful employment. By inference, there will always be a demand for marketable skills but there may not be a demand for "education." As a corollary, there are - and will be - people with engineering degrees that are in control of their lives. There will also exist other engineers who will have little or no such control.

Over the past four decades we have met with, and spoken to, many engineers in all age groups who claimed that matters are out of their hands. They told us they are unable to influence decisions that have significant future impact on either them or their respective employers. Why should that be the case? Can we not choose to do (or not do) all kinds of things that affect our future? For instance, we can choose to watch worthless TV programs aimed at the least common viewer denominator. Violent video games and

95% of the available TV programs will not benefit us at all. As of 2007, the average American watches over eight hours of TV each day. Suppose you were free to choose between "Seconds from Disaster" and "The Three Stooges". One of these programs would at least tend to groom you to be a better engineer; the other is simply a big waste of your time. Alternatively, we can decide to read a good book or relevant technical text to upgrade our language skills and increase our knowledge base. Reading is essential to the development of language skills. To communicate their ideas and add value to an enterprise, engineers must have a better vocabulary than many other crafts or professions. A widely read publication thus stated, quite correctly, that "many people lose their jobs not because of lack of technical skill, but because they lack the ability to communicate effectively". This observation is of great importance, since one obviously cannot communicate or express oneself effectively with flawed grammar.

A person with true marketable skills will not treat language with contempt and risk being refused a potential job offer or jeopardizing a job presently held. When you write, avoid spelling mistakes. Make sound and proper communication one of your most important learning objectives. Good communicators will always enjoy a far better probability of finding and maintaining employment than the non-caring rest of the bunch. So, pay close attention to Mark Twain, who said: "A man who chooses not to read is just as ignorant as a man who cannot read."

Know the Definition of "Engineer"

If you are young and wish to acquire engineering skills, start by knowing the definition of "engineer." In some countries of Continental Europe and Latin America, the mere title "engineer" is limited by law to people with an engineering degree, and the use of the title by others (even persons with much work experience) is illegal.

In Italy, the title is limited to people who, besides holding an engineering degree, have passed a professional proficiency exam.

Laws exist in all U.S. states and in Canada that limit the use of certain derivative or explanatory engineering titles. In particular, the title "Professional Engineer" is limited, as are often titles indicating a specific, regulated branch of engineering (such as "civil engineer" or "mechanical engineer").

Nevertheless, most U.S. states do not restrict unlicensed persons from calling themselves an "engineer" or indicating branches or specialties not covered by the licensing acts, though the legal situation regarding the title of "engineer" in Canada is unsettled. Again, the situation is entirely different for engineers wishing to use the designation P.E., the letter "P" indicating "Professional." Use of the P.E. title is restricted to licensure by individual States. The same is true in Canada, where the designation "P. Eng." is being used. The status of maintenance and reliability engineers is unclear and has been the subject of debate for decades.

In general, engineers in the United States are not held in the same esteem as, say, medical doctors. Some of this is cultural and may never change. If, in the United States, Hubert Google is a medical doctor, he's likely addressed as Dr. Google. If he's an engineer, he's more likely addressed as Hubie. We will leave it to the reader to determine which of the two ways of addressing professionals conveys more respect.

Nevertheless, it might be worth noting the specific experience-based remedies that have, in the past, and will, in the future, allow perceptive engineers to climb out of the rut in which others apparently find themselves. But first, some background information.

Success as an Engineer: Choices To Be Made

In 2007, guidance from more experienced co-workers is often unavailable. The novice engineer may end up reporting to someone who never expressed his, or the company's, expectations in plain English. Moreover, expectations have often been misdirected by a superior whose own background has nothing to do with the various engineering disciplines reporting to him.

The situation was different in the 1950's and 1960. A mechanical engineer's career was then largely influenced by supervisors and managers who had moved through the same, or at least similar, knowledge related career steps. Guidance and direction given in the mid-20th century was thus far more focused than offered today by early 21st-century generalists and money-management types. The world view of today's boss is often shaped by motives and forces that differ substantially from those a few decades ago. As one of the consequences, far fewer engineers today are being enabled and empowered to act as decision makers.

Remember that we make many choices every day. While time and unforeseen occurrences befall anyone, our lives are largely influenced by the choices we make. A young engineer can choose to get virtually all of his or her post-college training in the form of on-the-job learning. Although there is certainly nothing wrong with absorbing and thinking on-the-job, engineers that want to be in control of their lives must buttress and supplement this learning with mature reading habits. Mature reading habits will unquestionably accelerate the acquisition of thoroughly marketable skills in more structured ways than traditional on-the-job learning.

The Engineer and On-The-Job Training

A measure of on-the-job training is always appropriate. It acknowledges that we can always learn from others. However, we must guard against accepting and absorbing as "fact" whatever others tell us; it certainly will not always be of true benefit. Conversely, the act of discarding everything that others have done before us would not be a very smart approach either. In essence, either extreme must be avoided, and science must always trump gullibility and sales pitches. Testing and understanding "the mechanics of things" and even thoroughly examining underlying thought processes are always sensible choices.

This again implies that you should seek a balanced view, and that finding and consistently practicing this balance requires a conscious effort. While it is certainly never too late to cultivate a balanced view, it is obviously best to do so early in one's life. This cultivating requires an investment in time; it certainly implies reading and thinking not just on one's employer's time, but also on one's own time. On the other end of the spectrum, we should not "study things to death" since there are many endeavors that simply do not merit investigation beyond a certain point. Again, this is a matter involving common sense and balance.

Shared Learning and Specialization are Important

When a person learns or adds experience in a field that is logically related to his or her job function, both employee and employer stand to benefit far beyond their original expectations. The employee gains a sense of self-worth that will allow him or her to confidently look ahead to an otherwise hazy employment future. By nurturing the desire to learn in an employee, an employer stands to gain a value-adding contributor. This contributor's future ability to make go-no-go decisions that are based on fully understanding risks and consequences can be worth a fortune. A smart employer, therefore, makes training a shared responsibility. Both employer and employee will consistently and conscientiously carry out their respective obligations.

If, then, you accept there is merit in having control over your life and future, it would be your desire to increase your marketable knowledge. You would take steps to systematically acquire a definable specialty and strive to know, ultimately, how you measure up against real-world competition. Having accepted and acted on these premises allows you to go into a job interview with greater confidence.

The Job Interview and Beyond

So, let's just assume you are a novice mechanical engineer with the goal of specialization in rotating machinery for oil refineries and petrochemical plants, or reliability improvement of fluid machinery (pumps, turbines, compressors). Note that this arbitrarily chosen specialization goal is not as narrow as, say, "small metering pumps." An overly narrow area might not serve you in the long term if, for instance, small metering pumps were suddenly being replaced by "miniature nano-electronic stroking pistons"- or whatever. Likewise, an overly broad area of specialization (such as "machinery and equipment") might be presumed to include bookbinding, and packaging, and shoe manufacturing, and ten thousand other types of machines. Expressing the desire to cover such a wide area during a job interview will likely be perceived as shallow or unrealistic.

Don't come to your job interview in beach clothing and flip-flops. The interviewer may not admit that he or she was stunned by the multicolored depiction on your neck of Saint George slaying the dragon but, rest assured, the job will be offered to someone else. However, let's suppose you can count yourself among the fortunate ones not handicapped by this potential problem. In that case, show initiative during the job interview. If you're an engineer about to graduate, ask about the training opportunities made available at, or endorsed by, the prospective employer's facility. A serious interviewee must have a goal in mind and this goal must involve professional growth and learning.

Learning is obviously a two-component process. While one party offers it and the other absorbs it, the ultimate benefits are shared by both. That being the case, each has a commitment to make and serious forethought and mutual cooperation are needed to achieve optimized professional training. During a job interview, a graduating engineer would be wise to explore his or her projected role. Certainly soon after starting work, the engineer should be strongly interested in receiving a written role statement from his or her superior. If no such statement is forthcoming, the engineer may put his or her understanding on paper and ask the responsible manager for review, input or concurrence. Unless there is agreement on the engineer's role, a rating such as "performance exceeding expectation" will be, at best, elusive and, at worst, unattainable.

As an example of systematically adding value to employer and employee, a company could identify a self-motivated employee and ask this person if he or she would be willing to be the custodian of an electronically stored and searchable engineering library dealing with turbomachinery, pumps, gears, shaft couplings, etc. He or she would then be asked to locate useful Conference Proceedings, published articles and related information on the chosen topic. The material needs to be indexed and, in one form or another, made accessible to one's peers and other individuals that would be helped by the reference material.

During performance appraisals, the employee and the reviewer/appraiser would make an objective assessment of accomplishments by way of comparison with the previously agreed-upon role statement. Such an assessment would comprise all pertinent training issues and would obviously include measuring the employee's performance with regard to reading and disseminating technical material.

Specific Steps in the Training and Learning Process

Just to re-emphasize: the first and perhaps most important, step in an engineer's training is accepting that the most important learning process begins at graduation. Yet, even an engineer with a commendable history of prior employment should concede that profession-related training starts in earnest after you have accepted a job offer.

Our premise is very simple: To be gainfully employed with continuity, you need to set yourself apart from the indifferent crowd. While the specific training plans differ for various roles and job functions, the principles remain the same. Therefore, as we list components of a training plan for the role of "reliability improvement of fluid machinery", remember that the general principles derived from this example apply to every other aspect of engineering.

Reading Trade Journals

In the interest of continually obtaining work-specific technology updates and related training, the developing engineer must peruse applicable trade journals. He or she should scan and-- either by eye or electronic scanner-- retain articles on topics of potential interest. Use your imagination to interpret "scanning" as viewing and making copies of, or reading, tearing out pages, filing away and cataloging articles.

Companies with well-defined training plans arrange for applicable Trade Journal "1" to be given to employee "A". As he notices an article dealing with shaft couplings, he sends copies to colleagues or co-workers "B", "C", "D", etc. Applicable Trade Journal "2" starts its route at the desk of employee "B" who notices articles of pivoted shoe bearings and wear-resistant V-belts. "B" makes copies of these and sends these copies to "A", "C", "D", etc.; likewise "C" sends articles to "A","B", "D"," E", and so on.

This once-per-month review task typically takes less than 10 minutes per month and allows each participant to acquire a data bank of relevant cross-references. I have personally had an experience decades ago when I looked for a reference article and then contacted its author, asking for - and cheerfully receiving - priceless guidance on a subject matter related to his article.

Technical Books: One Page a Day, or 200 Pages per Year

Few engineers purchase or thoroughly read technical texts after completing their formal education. Fortunately, however, there are some concerned employers who recommend that their staff read and absorb relevant technical texts. In 2003, one such employer encouraged his responsible professional employees to purchase as many books as they could reasonably assimilate or digest in a year's time.

During performance appraisals, the effectiveness of this policy is continually being tested, validated, ascertained and reaffirmed. Another company purchased pertinent technical texts and required each technical employee to read a page per day.

To the extent feasible and reasonable, these professionals are then asked to jot down what they discern as differences between their work processes, hardware details, failure frequencies, maintenance intervals, work processes, etc., versus what others (competitors) are doing in these fields. The training value is immense. Certainly, the return on the investment of the time it takes to read a page-a-day and to make a two-sentence notation each week is huge. There can be no doubt that this well-focused training is priceless and benefits all parties for years to come.

Training Through "Shirt-Sleeve Seminars"

In the 1970's, one highly profitable company arranged for its equipment reliability technicians and engineers to share the responsibility of making 7 to 10-minute presentations at the end of each routinely scheduled and mandatory safety meeting. The presenters had to first educate themselves on such topics as "how to properly install a centrifugal pump", or "why steam turbines must be pre-heated before operation." Following the safety meeting and after making their add-on presentation, the equipment reliability technician or engineer would distribute laminated copies of these equipment-related single-sheet guidelines. Each employee had a three-ring binder in which he would place his copies. Plant management made sure that these guidelines were being used and adhered to by mechanical work force and operating personnel.

In this manner, the "shirt sleeve seminar" presenters taught themselves and passed on their findings to the entire plant. At this location, equipment failures due to human error and other causes were minimized and everyone profited from this approach. There should be no reason for not adopting it elsewhere with equal success.

By accepting help and by being willing to help others succeed, engineers will prosper. Moreover, they will gain a sense of self-worth if they truly pursue training. Engineers that succeed in acquiring a marketable skill both during formal studies and after graduating from engineering school can face the future with considerable confidence. Once you've been accepted by an employer and on your way to work every day, resolve to add value. Think ahead, dwell on the specifics of adding value on that day. Then, on the way home from work, ask how successful you've been in adding value to the enterprise. Finally, remember that in your job you may occasionally encounter leaders that either cannot - or will not - lead. When this happens, don't give up. Only dead fish always swim with the stream.

Favorable Results Anticipated

Self-motivated engineers or technicians who implement and stick to the approaches briefly described here are very likely becoming employees who offer solutions to problems. Instead of becoming folks expressing "concern" over potential problems, they will delineate the discrete steps needed to avoid problems.

There are, then, a few reminders for future maintenance and reliability professionals to ponder. First and foremost, not all that is labeled education is beneficial. Some education can be so academic as to lack substance; it would not pass as a marketable skill.

It's the same with training. Take charge and make it relevant. Instead of waiting for skill-enhancing training opportunities to present themselves, take a lead role in creating some of these opportunities. Recognize that virtually every marketable skill is acquired by tangible and well thought-out training steps.

Remember, it's the marketable skills that will get us through life far better than a mere education.

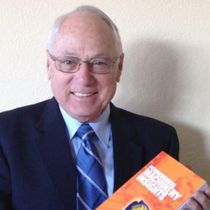

About Heinz P. Bloch

Heinz P. Bloch is a practicing professional engineer with over 45 years of industrial experience. Since his retirement from Exxon, he has been advising process plants on maintenance cost reduction and reliability upgrade issues. He is the author of 17 textbooks and over 350 other publications on reliability improvement, uptime extension and related topics.

His most recent textbooks deal with process gas compressors and related subjects. Mr. Bloch has also been the Keynote presenter at the Predictive Maintenance Technology Conference