The ABC's of Job Safety Analysis

The goal for organizations is job safety that is effective and adds the least possible overhead to the job. An overriding rule is that the safest environment is one where safety is involved at all stages of the job, starting with conception and planning.

Tacked on safety is expensive and ineffective.

One of the planning jobs is to break down maintenance activities into steps. This process helps identify resources, tools and start-up procedures and makes it easier to estimate. One other process made easier by breaking down the work is hazards identification.

As an example, let’s look at a job to remove and replace a large pump. Further, let’s agree that the job steps are as shown in Table 1.

Job safety analysis (JSA) is the process used to detect hazards and decide what to do with them. The purpose of a JSA is to ensure that the risk of each step of a task is reduced to as low as reasonably practicable (ALARP). Next, look at each step to see if any of the hazards from the list are likely, probable, or possible (i.e., high, medium, or low) probability.

If you take just a few steps from the job plan, as shown in Table 2, you can see what risks are present and, based on the impact and probability of occurrence, decide on a course of action.

Safety Data Sheets Basics

What Every Maintenance Leader Needs to Know

The most common mistake organizations make with safety data sheets (SDS) and chemicals is that the inventory of chemicals in use does not correspond to the SDS in the notebook or file. The fine in the U.S., as in other areas, runs from $7,000 per incident per day to $25,000 per incident per day.

To avoid being out of compliance, consider computerizing the whole process. In the U.S., the Occupational Safety and Health Administration (OSHA) accepts the presence of SDS in a computer. With networks, you can avoid trouble by having a company-wide file available to everyone.

Two important things to keep in mind:

- It is the manufacturer of the chemical that is responsible to get the SDS to you. You are responsible to notice if you have them or not.

- A major source of inspections originates from disgruntled employees anonymously calling OSHA.

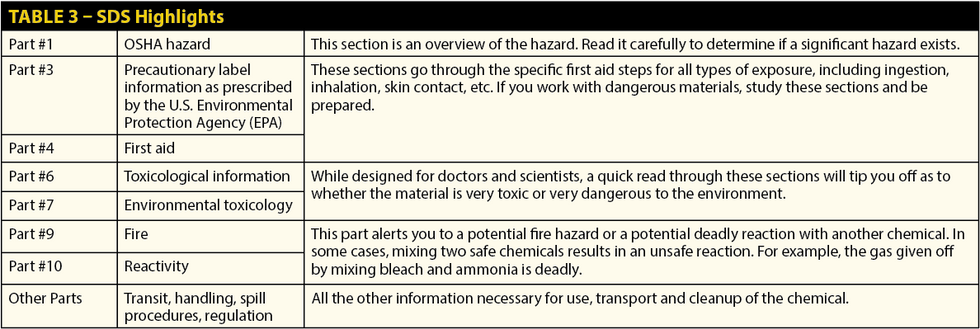

The exact format of the SDS varies by manufacturer, but there are general sections that contain critical information that every employee should know. Some SDS could have as many as 15 parts.

The Safety Meeting

One aspect of safety is the reminder to be safe! Just the actual reminder might save someone’s life. It’s not unreasonable to have a safety moment every day. It could be one or two minutes. At some companies, when they have any meeting, they always start with a safety moment.

In maintenance, there’s usually a five- or 10-minute section on safety during the daily toolbox meeting in the morning; nothing really elaborate. If you’re going to address a bigger safety topic, it might be a half hour or an hour with a slide presentation.

It could be a single point lesson. For example, you might discuss fatigue. Fatigue is the most common cause of accidents because when you are tired, there is more of a chance of injury. Another important topic might be slipping and tripping. Slipping and tripping is the second most common cause of accidents, which can be avoided with improved housekeeping and better lighting.

OSHA has some really great material for safety meetings that you can access from its website (osha.gov/SLTC/text_index.html). This material is available to anyone, anywhere in the world. There are literally enough topics there to last a year.

Among the topics available are: confined space; disease prevention and blood-borne pathogens; electrical hazards; ergonomics; hearing conservation; ladders; hazard communications; lifting toolbox with care; rigging; LOTO; office issues; PPE; seasonal toolbox dealing with seasonal issues or holiday awareness; slips, trips and falls; fatigue; fire; forklifts and forklift driving; small tools toolbox for small hand or powered tools; and weather and how it affects safety.

You could also base topics on the top fatal safety incidents, as shown in Table 4, or the top safety issues in a particular year, as listed in Table 5.

Frequency for Covering Key Topics

You should cover an important topic every couple of months, perhaps covering a different aspect of it each time.

To make the topic relatable, considering telling real-life stories. Here’s an example:

A guy bent over to pick up a tool and collapsed. His buddy standing next to him, thinking he’s having a heart attack, bends over to help him and he collapses, too! It turned out there was a chest-high level of carbon dioxide, so as long as they were standing up, they were fine.

The problem was they did oxygen sensing at head level. If they had done it up and down their entire body, they would have known there was an issue and accommodated it.

A lot of people don’t know about oxygen sensing, so using oxygen sensors correctly would be a good single point lesson. Operational experience is not helpful if you don’t know the things behind it. People get hurt by all kinds of crazy stuff. Telling those types of stories is useful.

Be careful with contractors. Include them in the meetings and introduce them around. However, be aware that contractors have a unique situation compared to in-house people. Every single day, contractors are facing a different set of hazards because of the different locations. So, you want to discuss what’s going on at that site. Don’t begrudge them the time to look at the hazards, such as slippery surfaces, construction going on around them, the position of cranes and heavy lifts, and overhead power lines.

Keeping Records

Keep a log of topics so you know what you are covering. It is also helpful for planning your next meetings. The talks should be held on company time and cover the hazards that your organization faces. You should also keep a record of who is in attendance, such as an attendance or sign-in sheet.

Why Go to All This Trouble?

- You made a promise! Check your mission, vision and value statement. Safety is one of the core promises to your employees and communities.

- Safety incidents create a bad public image.

- Compliance with regulations, laws and standards saves fines and keeps your company out of the news.

- There is an argument that safety saves money. When you consider the overall costs of accidents, a safe organization seems to always be the lowest cost producer.

- Many programs, such 5S, increase operational efficiency and promote safety.

- People avoid having accidents and having their friends hurt. Safety might improve employee satisfaction (or at least reduce dissatisfaction).

Downloads

Shop Safety Audit and Inspection Forms

References

- Checklist adapted from and courtesy of HP Hood LLC, through American Society of Safety Engineers www.asse.org/practicespecialties/transportation/

- Canadian Centre for Occupational Health and Safety. OSH Answers Fact Sheets: Inspection Checklists – Sample Checklist for Manufacturing Facilities. https://www.ccohs.ca/oshanswers/hsprograms/list_mft.html

- Work Safe Victoria, Australia. Tools to Help You Create a Safe and Healthy Workplace. https://www.worksafe.vic.gov.au/

- U.S. Department of Labor, OSHA. QuickTakes online bimonthly newsletter. osha.gov/as/opa/quicktakes