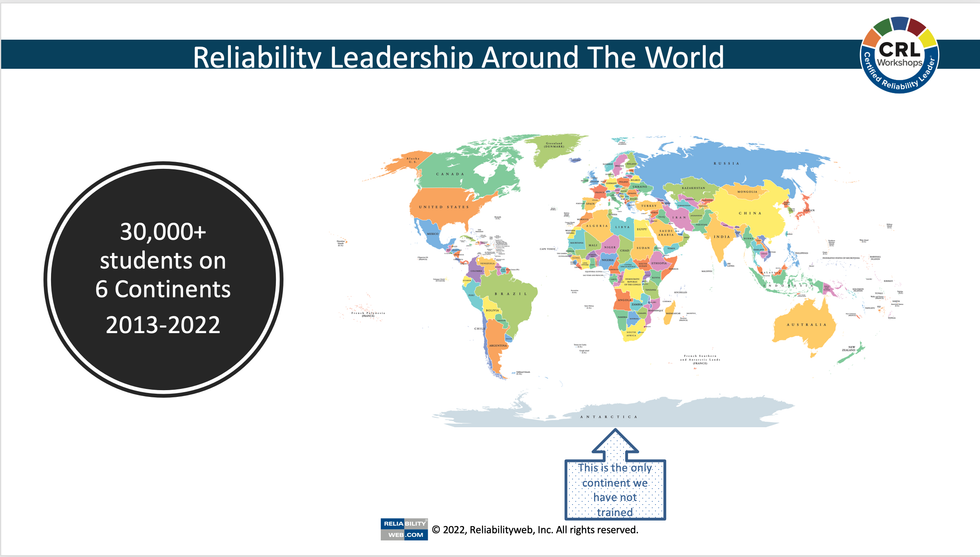

Our work with Uptime Elements Reliability Framework and Asset Management system has taken us to 6 continents and allowed us to train 30,000+ Reliability Leaders since 2013.

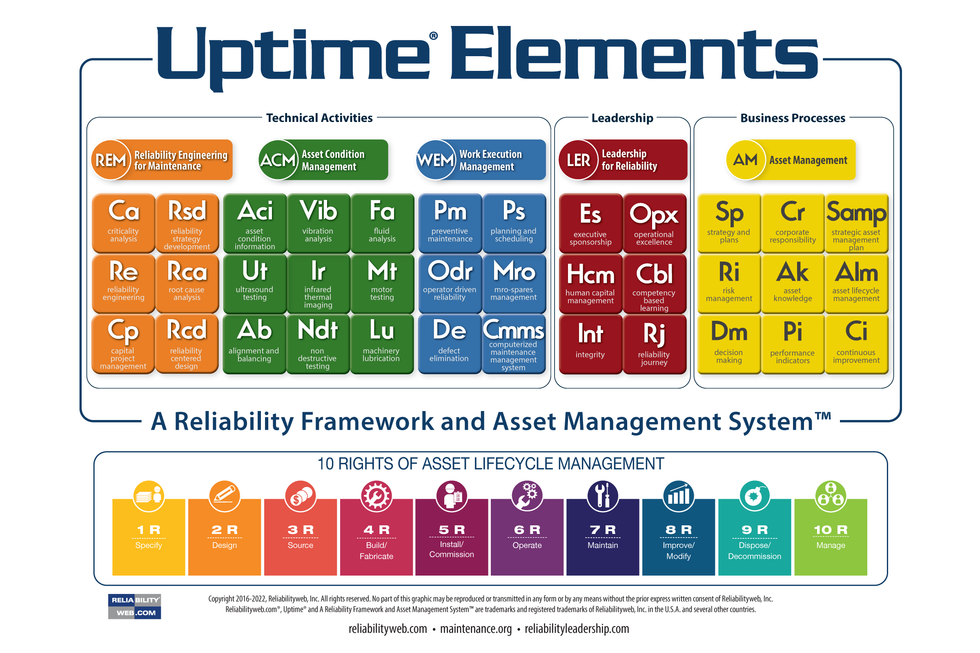

Uptime Elements Reliability Framework and Asset Management System is dualistic in that it is both Holistic in structure, while allowing complete deconstruction and itemized, individual approaches through customization, morphing and reconstruction into the journey that is the most appropriate for the organization, based on its objectives, business context and stakeholder concerns.

Uptime Elements Reliability Framework and Asset Management Systemreliabilityweb.com

Uptime Elements Reliability Framework and Asset Management Systemreliabilityweb.com

Simply put, we have been humbled being able to be part of so many powerful and significant enterprise journeys and we continue to learn more effective approaches for transformation.

One thing that is universal and often overlooked is the role of Reliability Leaders in repeatedly and continuously providing clarity on two import questions most team members have:

1) Who are we? The people in the organization want to know, understand and be empowered to strive for their contributions to deliver the aim, mission, vision and values of the cultural and operational sides of the organization

2) What is the plan? The people in the organization want to know what the policies, strategies and plans to achieve the objectives, how they will be resourced and how will they be measured toward success.

As a Reliability Leader, what are the ways you provide clarity on these two questions for your team?

Please find me at LinkedIn share your ideas, experience and knowledge

I am grateful

Terrence O'Hanlon

From Your Site Articles

Related Articles Around the Web

Uptime Elements Reliability Framework and Asset Management System

Uptime Elements Reliability Framework and Asset Management System