Under ISO55000, a company must demonstrate that it is managing its assets from project phase to end of life. However, at many companies, the creation of maintenance, repair and operating (MRO) spare parts master data is typically done very badly at the project phase and continues into the asset ownership phase. But, by developing an ISO55000 improvement program, companies can realize significant savings.

The ISO55000 asset management standard states that for assets, in particular spare parts, a company must:

- Demonstrate it is managing its data (e.g., cataloging, issue, returns, receipts, etc.);

- Have procedures in place (e.g., cataloging, initial spares purchasing, inventory management);

- Demonstrate risk-based decisions;

- Demonstrate continuous improvement.

Audits show that companies in almost every industrial sector have an ineffective MRO spare parts master data. to duplicate stock, loss of time trying to find spare parts, emergency purchases and excess stocking. The end result is excess costs.

Depending on how bad a company’s MRO spare parts master data currently is, there is a potential for significant savings by developing an inventory reduction process. One such inventory reduction process is based on the following phases:

- Audit;

- Define Processes and Guides;

- Cleanse;

- Rationalize;

- Optimize;

- Measure Effectiveness.

Phase 1: Audit

The first step for any inventory improvement program is understanding the company’s issues. The scope of a complete inventory management audit should cover these areas:

- MRO Best Practices – A structured questionnaire is used to evaluate best practices in managing spare parts effectively;

- MRO Written Procedures and Guides – The documents developed to cover each phase of an item’s life;

- MRO Master Data Review – Review of inconsistencies in short description that includes manufacturer and vendor part numbers and names, review of duplicates, etc.;

- MRO Inventory Replenishment Control Parameters – An evaluation of current reorder point (ROP), operational qualification (OQ), minimum-maximum, appropriate strategy used to replenish, etc.

The main focus for this article is activities related to spare parts master data.

A company’s inventory data is mapped and imported to an auditor tool containing filters and queries to facilitate the master data review. A report details the findings, good and bad. Remember, poor cataloging represents potential savings.

Typical findings of MRO master data audits are:

- Short descriptions have inconsistent formatting;

- Qualifiers or modifiers are not identified;

- Manufacturers’ names included in the short description for generic material;

- Lack of attribute data in the short description or inconsistent sequencing of the attribute data;

- Manufacturer part numbers (MPNs) have inconsistent formatting and often contain a mix of both vendors’ and manufacturers’ part numbers;

- Between 10 to 15 percent duplicate line items;

- Abbreviations are not used when they should be or they are inconsistent;

- Multiple suppliers for similar material;

- Standardized part names are not always used to name parts.

Figure 1: Excess use of modifier general

Figure 2: Extract unique list of O-ring material

Figures 1 and 2 are two typical examples of poor cleansing delivered by a consultancy company.

Figure 1 shows that even after cleansing, one is unable to identify the type of bush and its size.

Figure 2 is an extract from the O-ring bearing material identified. There is no standardization of the material, resulting in 39 different variations.

Phase 2: Define Processes and Guides

ISO55000 states that a high-level strategic plan, known as a strategic asset management plan (SAMP), needs to be developed. The structure of the SAMP varies between consultants and the various maintenance associations. This is because ISO55000 is not prescriptive. For this article, the SAMP includes two elements relative to MRO spare parts:

- Initial MRO Spare Parts Planning (Project phase);

- MRO Spare Parts Management (Ownership phase)

The main reason for poor cataloging is that the cataloging process is not documented in the project phase, which includes the computerized maintenance management system (CMMS) population.

Often, with cataloging by consultant or engineering contractors, the cataloging or the cleansing has been poor. Unless you document all the rules and build criteria, the cataloging will include inconsistencies.

Remember, under ISO55000, you must demonstrate the management of data and that means how the data is populated in the CMMS consistently.

Documentation can include:

- Guides and rules agreed and used during the cleansing;

- A list of all abbreviations;

- Type guides to cover the type of spares stocked and the agreed naming convention.

Figure 3 shows a typical type guide for shaft bushes.

Figure 3: Shaft bush type guide

Phase 3: Cleanse

The scope of cleansing the master data varies from company to company and is CMMS dependant. For example, users of one software solution may be able to describe their spare parts using up to 75 characters, while users of another are limited to 40 characters. This means users limited to fewer characters must use many more abbreviations to describe a spare part.

A tool for creating business applications may be an ideal solution when developed with standardized part descriptions and standardized template descriptions.

Another reason for duplicate line items is that manufacturers and vendors use different naming conventions. For example, to express a stainless steel part, they might use A2, 304, or SS. Any specification differences can make identifying duplicates difficult. Therefore, Phase 2 is essential. You must clearly identify your naming and specification standards.

Benefits of cleansed master data are the identification of potential duplicates, ease of finding spares, identification of standardization and rationalization opportunities, and inventory reduction.

Figure 4 shows a comparison of current part descriptions and the cleansed descriptions.

Figure 4: Before and after cleansing part descriptions

Phase 4: Rationalize

Rationalization is about reviewing your material and seeking inventory or cost reduction opportunities. Companies that have proceeded to the cleansing and rationalization phases have achieved a 60 to 70 percent reduction in line items for some material by:

- Standardizing part descriptions and MPNs;

- Removing duplicates;

- Standardizing material specification;

- Reducing the number of manufacturers;

- Removing stock that is not fit for purpose (i.e., wrong specification).

Rationalization covers several tactics, including:

- Assigning classifications for ABC, HML and XYZ approaches and demand classes;

- Identifying original parts manufacturers (OPMs) and advanced parts manufacturers (APMs);

- Standardization and reducing the number of manufacturers stocked;

- Reducing stocking locations;

- Conducting root cause analysis (RCA) for A items;

- Conducting spend analysis.

Figure 5: Assigning ABC to a data set

Figure 6: Shows 31 manufacturers of bearings

Figure 7: Number of line items by bearing manufacturer

Figure 5 shows what a query looks like after assigning ABC to a data set based on annual issue value (AIV).

Figures 6 and 7 show an analysis of manufacturers’ parts stocked and forms the basis for a rationalization study.

Further cost savings are likely by proceeding to Phase 5, MRO optimization.

Phase 5: Optimize

Optimization supports ISO55000 by making decisions based on risk. A stock out risk is set for each spare part based on the item’s criticality. Opportunities for reducing inventory are identified by determining the optimum ROP and OQ and then the most appropriate replenishment strategy.

Optimum ROPs and stocking levels are determined by:

- Assigning a service level to each spare part based on its criticality;

- Identifying the true lead time that includes company plus supplier;

- Determining the average demand rate;

- Calculating existing and optimum metrics;

- Identifying reduction opportunities;

- Challenging the stocking of slow moving parts.

The three main replenishment strategies are:

- ROP: a fixed ROP and OQ;

- Min-max: a variable OQ to bring the stock level to a maximum;

- Constant vendor delivery: based on just-in-time (JIT) concepts.

Potential cost savings can be identified by looking for them. Prioritization is based on the differential financial value between the current average stock level and optimum average stock level.

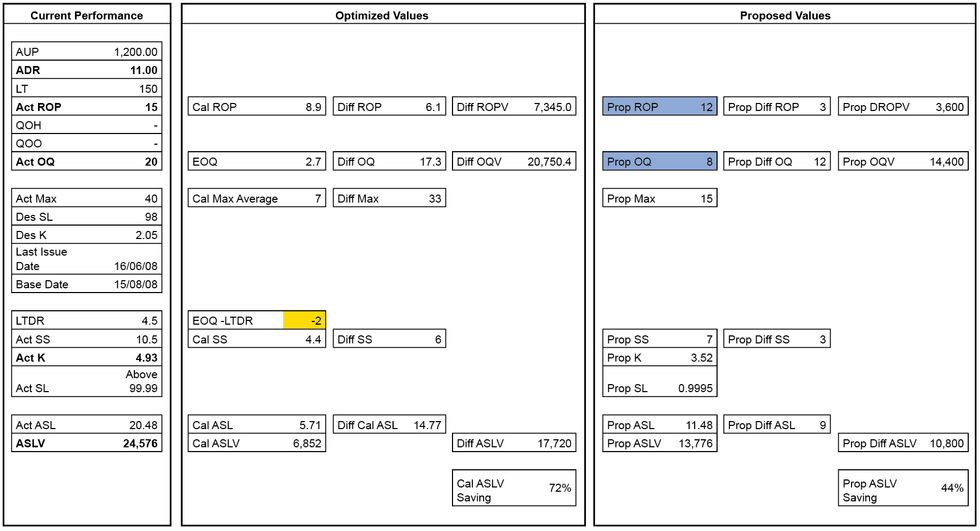

Figure 8 is from a case study where the optimum values are not appropriate. The options, then, are to either: (a) increase one or more control parameters, for example OQ, so they are not the optimum values or (b) move to a different replenishment strategy.

In this example, the first option (a) was considered the most suitable choice. Figure 8 shows current performance, the optimized performance and the proposed performance. The proposed performance delivers 44 percent savings. If the company was to implement the optimized parameters, it would introduce a higher risk of a stock out.

Figure 8: Optimization analysis

Phase 6: Measure Effectiveness

This phase would include activities such as:

- Reporting performance using key performance indicators (KPIs);

- Monitoring usage in line with predictions;

- Monitoring stock balance and taking action— the balance is always above safety stock or there are stockouts;

- Conduct spend analysis.

Summary

A structured approach to inventory reduction can deliver significant results and help companies make their MRO spare parts program ISO55000 compliant.

From Your Site Articles

Related Articles Around the Web