"Planning is bringing the future into the present so that you can do something about it now." - Alan Lakein

Introduction

The Key to True Asset Management

If one considers asset management as caring for the assets of an organization, then it is true that work execution management enables asset management. If one considers that reliability engineering for maintenance and asset condition management generates the work to be performed, then work execution management is the process in which the work is accomplished. If the work is not accomplished, then reliability engineering for maintenance and asset condition management for maintenance both become academic exercises.

The Body of Knowledge

The body of knowledge for Work Execution Management or WEM is comprised of books and articles that deal with work execution. This includes books and articles on preventive maintenance, maintenance organizational design, planning and scheduling, operator driven reliability and maintenance, repair and overhaul (MRO)-spares management. Adopters of work execution management are advised to read publications dealing with each of the elements that comprise WEM before beginning implementation.

Creating an Asset Management Culture

So much of what is accomplished in WEM relates to the culture of the organization. It relates to the organization being reactive or proactive. In a reactive organization, WEM best practices seldom exist; the culture is “fix it when it breaks.” This leads to excessive maintenance costs and high equipment downtime. In a proactive organization, work activities are planned, scheduled and executed at the lowest possible maintenance costs and minimum equipment downtime. While there is no organization that is purely reactive or proactive, most will tend to focus on reactive work. Moving from a reactive to a proactive culture is one of the most challenging missions in developing a work execution management culture.

Its Place in the Uptime Elements

Regardless of how good your maintenance strategy is, it is your organizational culture that will determine its performance. Culture is built from within and is cultivated by leaders who are trying to engage employees in developing and enhancing the performance of the organization.

The Uptime® Elements™ framework, shown in Figure 1, provides a map of tools and techniques for understanding asset leadership and creating a culture of reliability. WEM provides powerful culture building tools, such as defect elimination and planning and scheduling. In addition to the obvious tangible asset performance benefits delivered, the Uptime Elements framework begins to change the organizational culture from reactive to proactive. The proven approaches to successful work execution management provided in this guide are represented by the work execution management elements pictured in blue on the Uptime Elements chart in Figure 1. The combination of technical excellence and empowered leadership at all levels is by far the most significant indicator of a successful work execution management process and an organization that delivers significant results.

Figure 1: The Work Execution Domain from the Uptime Elements Reliability Framework and Asset Management SystemTerrence O'Hanlon

Figure 1: The Work Execution Domain from the Uptime Elements Reliability Framework and Asset Management SystemTerrence O'Hanlon

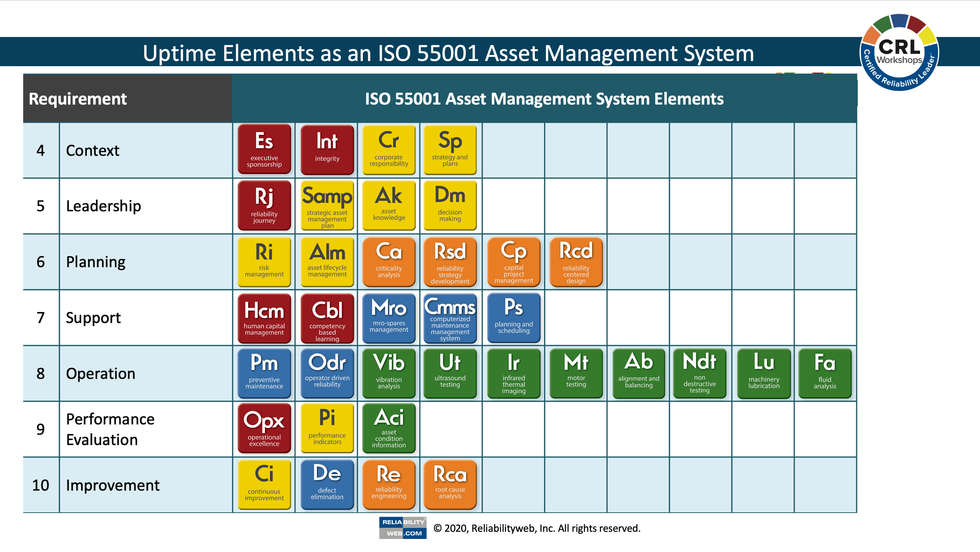

The Uptime Elements framework works seamlessly with the International Organization for Standardization’s (ISO’s) asset management standard as shown in figure 2. According to the ISO55000 asset management standard, an asset is a thing that has potential or actual value to an organization. Asset management is a coordinated set of activities to realize that value. Uptime Elements work execution management enables asset management by assuring the reliability and full function of the assets when value is demanded.

Figure 2: Uptime Elements as an ISO 55001 Asset Management SystemTerrence O'Hanlon

Figure 2: Uptime Elements as an ISO 55001 Asset Management SystemTerrence O'Hanlon

The WEM Knowledge Domain aligns with the ISO standard and Uptime Elements framework. WEM's recipe for success is derived from industry best practices learned and communicated by dozens of practitioners involved in creating the body of knowledge behind them. Reliabilityweb.com has hosted several industry conference forums that contributed content to this guide and many authors have contributed examples and sections to this work.

Most recently, Reliabilityweb.com convened a working group to develop this WEM guide and reflect best practices common to all major work execution management approaches and capture lessons learned from organizations deeply involved with WEM. We will be publishing this work in several parts in the coming weeks.

WEM Process Overview

The work execution management domain of Uptime Elements consists of six major elements:

- Preventive maintenance;

- Defect elimination;

- MRO-spares management;

- Planning and scheduling;

- Computerized maintenance management systems

Preventive Maintenance

Preventive maintenance forms the foundation for the WEM domain and focuses on basic inspections and services of the equipment. This is to ensure that work can be identified, planned, scheduled and executed in a proactive mode. If an organization is good with conducting basic inspections and routine services, equipment problems are greatly reduced. The goal of a preventive maintenance program is to reduce the amount of reactive maintenance work to less than 20 percent of all activities. Organizations that are successful with their preventive maintenance programs easily achieve this objective.

Defect Elimination

Defect elimination can be conducted as part of the preventive maintenance program or as a separate activity where the entire organization focuses on elimination of defects. What are these defects? They result from basic activities that operations and maintenance personnel perform on the equipment to eliminate breakdowns or equipment capacity reductions. If these activities are not performed at a precision level, small defects are introduced into the equipment. Helping everyone who interacts with the equipment to perform their activities at a precision level contributes to defect elimination. A properly implemented defect elimination program should reduce the amount of reactive work in an organization to less than 10 percent of all activities.

MRO-Spares Management

MRO-spares management is the management of all spare parts for plant equipment. MRO-spares management includes activities, such as ordering spare parts, receiving spare parts, binning spare parts, and issuing and returning spare parts. It is necessary to have documented process flows for these activities to ensure the organization consistently completes them. It is also necessary for MRO-spares management to provide 95 to 97 percent service levels for spare parts in order to begin planning and scheduling.

Planning and Scheduling

Planning and scheduling is the coordination of maintenance activities to ensure there are no work delays due to logistics. These delays include equipment not properly shut down, no spare parts, or wrong skills sent to the job. Planning and scheduling should be performed for at least 80 percent of all maintenance activities, with schedule compliance greater than 90 percent. One of the major enablers to successful planning and scheduling is a correctly structured maintenance organization, which will be covered later in this guide.

Computerized Maintenance Management System

A computerized maintenance management system (CMMS) is an electronic system utilized to manage all maintenance activities. This computerized system is used to generate preventive maintenance tasks, manage materials, and plan and schedule all maintenance activities. If used correctly, a complete history of all activities performed on the equipment in the plant is readily available for analysis.

Operator Driven Reliability

Operator driven reliability (ODR) is a process whereby the operators are involved in some activities on their equipment that enhance reliability. ODR also may involve transferring some tasks typically performed by maintenance to the operators. ODR eliminates equipment downtime and frees up maintenance resources so they can be redeployed in higher level predictive or reliability activities. ODR involves operators in 10 to 40 percent of all preventive maintenance activities.

Criteria for WEM Improvement

WEM Organizational Readiness

Through a step-by-step process, virtually any organization can improve in work execution management. To properly structure WEM improvement, it is necessary to know the current status of the organization. Numerous analysis tools are available for this purpose; some very extensive, others too basic to provide a valid analysis.

A powerful assessment tool based on Uptime Elements is RAM GPS by Asset Analytix

RAM GPS Powered by Uptime Elements

RAM GPS Powered by Uptime Elements

You’ll be amazed at the results you can achieve through the RAM GPS assessment!

A streamlined new approach to assess your Reliability & Asset Management (RAM) program; RAM-GPS is the first ever high-level assessment tool aligned around Reliability Web’s UPTIME Elements Framework.

Convincing the Organization

Once the strengths and weaknesses of the organization are highlighted, the next step is to discuss how to convince the organization to invest in and implement a work execution management process. This step is divided into four primary topics:

1. Financial impact;

2. Senior executives;

3. Peers within the organization;

4. Subordinates.

Financial Impact

The four areas of financial impact are:

- Maintenance labor;

- Maintenance materials;

- Maintenance shutdowns, turnarounds and outages;

- Asset downtime.

- Maintenance Labor

Maintenance productivity in most U.S. companies averages between 20 and 30 percent. This translates into approximately two hours per eight hour shift of hands-on activities. Most of the lost productivity can be attributed to these reasons:

- Waiting on parts;

- Waiting on information, drawings, instructions, etc.;

- Waiting for the equipment to be shut down;

- Waiting on rental equipment to arrive;

- Waiting on other crafts to finish their part of the job;

- Running from emergency to emergency.

While 100 percent productivity is an unrealistic goal for any maintenance organization, a more realistic percentage of 60 percent is achievable.

Productivity of maintenance technicians can be improved by concentrating on basic management techniques, such as:

- Planning jobs in advance;

- Scheduling jobs and coordinating schedules with operations;

- Arranging for parts to be ready;

- Coordinating tools, rental equipment, etc.;

- Reducing emergency work below the 50 percent level through preventive maintenance.

With computer assistance, planning time per job can be reduced, resulting in more jobs planned and coordinated. This allows more time for preventive maintenance activities, which, in turn, help reduce the amount of emergency and breakdown activities. This results in fewer schedule changes and helps increase productivity by reducing travel and waiting times. Successful organizations implementing WEM have indicated an increase in productivity of up to 28 percent.

Maintenance Materials

Material costs are related to the frequency and size of the repairs made to the company’s equipment. The sheer number of parts, in addition to stores policies, purchasing policies and overall inventory management practices, contribute to the overall maintenance materials cost. Since little attention is paid to maintenance materials in some companies, inventories may be higher than necessary by some 20 to 30 percent. This increases inventory holding costs and makes materials unnecessarily expensive. The inability of stores to service the maintenance department’s needs results in “pirate” or “squirrel” storage depots for just in case spares. This practice also drives up the cost of maintenance materials. With materials making up 50 percent of the total maintenance costs, this is an area where improvement is necessary.

Good inventory controls enable companies to lower the value of their inventory while still maintaining a service level of at least 95 percent. This allows the maintenance department to be responsive to the operations group, while still increasing its own personal productivity. Successful WEM implementations have averaged 19 percent in lower material costs and an overall 18 percent reduction in total inventory.

Maintenance Shutdowns, Turnarounds and Outages

In many companies, maintenance is involved in project, shutdown, outage, or refurbishing activities. These activities, if not properly controlled, can have a dramatic impact on the company’s production capacity. That’s because these activities are usually performed with the equipment in a down condition, meaning no production during this time. For this reason, any amount of time that can be eliminated from the project, outage, or refurbishing can be converted to production time. In the refining and power generation business, the cost of a prolonged outage is prohibitive.

Improved planning and coordination can be achieved with a robust WEM process. This will often help shorten the downtime, even if the company is currently using a project management system. Successful WEM processes have allowed companies to achieve up to a five percent reduction in outage time.

Asset Downtime

Reduced downtime costs are the true savings for a company determined to improve maintenance policies and practices. The downtime cost for equipment may vary from several thousands of dollars per hour to literally hundreds of thousands of dollars per hour. One company with several production lines in its plant had downtime on each worth $1 million for 24 hours.

In some companies, levels of downtime can run as high as 30 percent or more. This results in lost sales opportunities and unnecessary expenditures for capital equipment generally put the company in a weak competitive position. By dedicating the company to enforcing good maintenance policies and practices and utilizing the CMMS as a tracking tool, equipment downtime can be reduced dramatically. Successful WEM processes have allowed companies to achieve a 20 percent reduction in equipment downtime losses.

Executive Sponsorship

Successful communications with senior executives must be done in the language of finance. At this level, they tend to be very bottom-line oriented. Problems develop because maintenance executives tend to communicate in a technical language. It is necessary to convert all technical benefits of WEM to financial terms to obtain senior executive sponsorship. This is extremely important since without senior executive sponsorship, WEM improvements have very little chance of success. Using the aforementioned four areas to financially justify all WEM improvements is a first step in communicating with senior executives. When senior executives see the possible savings that could come from the WEM improvement program, they then tend to view any expenses in setting up the improvement program as a return on investment. They realize that by spending some money up front, they have the potential to have large returns in the future. The return on investment time frame is important to understand. It is not a matter of seeing the return in a few weeks, rather executives must be willing to invest for three to six months to see the necessary changes that will produce long-term savings.

Peers Within the Organization

Communicating with your peers in the organization is also important. For them to understand WEM processes, they must be related to their existing processes. For example, if the communication is with the maintenance manager’s operational peer, the communication is likely to revolve around equipment downtime and throughput. By showing the operational manager the increased throughput that will be achieved by downtime reductions, the WEM process is more attractive.

With the other mentioned measures, the reduction in downtime should be something to communicate with the operations manager. If communication is with the engineering manager who is concerned about projects, the ability for maintenance to support projects through better planning and scheduling would be a key point in the communications.

Subordinates

When trying to develop bottom-up implementation support, selling WEM processes to subordinates is also important. This level of communication should revolve around how WEM will make their job assignments easier and more fulfilling. By increasing their productivity and eliminating work delays, those closest to the work will be able to take more pride in their activities.

If WEM processes are going to be successfully implemented, communication with the four groups identified in this section is extremely important. Without this level of successful communication, it is highly unlikely that any work execution management will ever be successful.

To learn more about using this framework, the Reliabilityweb.com team offers a one-hour, one day and three-day training on the Uptime Elements Reliability Framework and Asset Management System. Check the online calendar for a date and time that works for you and your team.

There is also an intensive Certified Maintenance Management [CMM] Workshop available that is 100% focused on Maintenance Management.

The CMM course is constructed of 18 modules aligned with the skills required to become a Certified Maintenance Manager.

You will leave the CMM session with a clear understanding of how to align with operational expectations and attain the stability and control that is required to enable maintenance.

Our goal is to train professionals in the asset management & maintenance reliability job fields to become leaders in reliability and to help attendees obtain the CMM Certification.

From Your Site Articles

Related Articles Around the Web

Figure 1: The Work Execution Domain from the Uptime Elements Reliability Framework and Asset Management SystemTerrence O'Hanlon

Figure 1: The Work Execution Domain from the Uptime Elements Reliability Framework and Asset Management SystemTerrence O'Hanlon Figure 2: Uptime Elements as an ISO 55001 Asset Management SystemTerrence O'Hanlon

Figure 2: Uptime Elements as an ISO 55001 Asset Management SystemTerrence O'Hanlon RAM GPS Powered by Uptime Elements

RAM GPS Powered by Uptime Elements